Geotextile Filter Used in Road Construction, Research Paper Example

Abstract

Geotextile use in road construction has empowered civil engineers to construct more economically efficient roadways. In addition to being a viable economic alternative for spreading pavement, it is also environmentally sound method as well. The ability of geotextiles to stabilize and strengthen surfaces while simultaneously supplementing the filtration process makes it and invaluable product for global manufacturing. The following research delves into the significance of geotextiles in the world today to demonstrate how its evolving the roadways.

Introduction

Geotextiles are widely used in geotechnical engineering to control erosion, improve the overall quality of a project, and to make projects more cost effective. Geotextiles are a major category of geo-synthetics and are made of fabric woven, sometimes with various materials, into a high polymer product. As noted in the Terram Limited geotextile brochure, “Within the construction and landscaping sector the use of geotextiles has become fundamental in solving an increasingly diverse range of global geotechnical and environmental problems (Terram Limited, n.d.)” Geotextiles essentially are the fabrics of our lives.

Synthetic materials used in the production of geotextiles were developed in the early 1920s, but it wasn’t until the development of more durable and project-specific fabrics in the 1950s and 60s that new kinds of geosynthetic building materials were created. These advances made in geosynthetic products lead to the geotextiles that are now widely used in geotechnical engineering. The early products were mostly permeable and made of spun and non-woven geotextiles, but later geosynthetic products were produced to be more ridged, like geonets and geogrids, or to be less permeable, like most geo-membranes. There are several different kinds of geosynthetic products that are currently available and they can all be divided by the property of their materials: geotextiles, geo-membranes, geogrids, drainage plates, geotubes, and a myriad of other materials with varying qualities.

This paper will focus on geotextiles, and specifically on the use of geotextiles in road construction. Geosynthetic products have become essential to the field of engineering. Many of the roads, levees, and even large-scale construction projects would be nearly impossible from a logistical and financial perspective if it weren’t for the development of competent geosynthetic materials. Anchoring the core of these geosynthetic materials are the geotextiles: the most common and widely used of the geo-synthetics. Geotextiles accomplish a wide array of important tasks like proving additional strength, forming flexible and porous barriers, and preventing damage to plastic liners. In road construction specifically, geotextiles help form a solid formation without requiring as much excavation or importation of aggregate. While newer technologies, materials, and methods of production have drastically changed the properties of geo-synthetics, geotextiles have remained the most commonly used type of geosynthetic in road construction because of their low cost, their ease of application, and the quantifiable strength and stability they provide to a project.

Background

Geotextiles to date are used in almost every highway project and can be found in most civil construction works. Throughout history engineers have had to find ways to build on weak soils. Since the 21st century geotextiles have served this purpose. They perform several functions, specifically reinforcement and separation beneath roads and embankments, as well as filtration in subsoil drains or behind rock seawalls.

The basic concept of geotextiles, which is the use of some basic fiber towards the re-enforcement of a soil structure, has been used in construction for centuries. The ancient Babylonians used woven reed mats to re-enforce the construction of their ziggurats and the Great Wall of China was reinforced with tamarisk. Comparatively speaking, the use of geo-synthetics in road construction, especially to the degree it’s current use, is a fairly recent development in engineering. In the United States in 1926, the South Carolina Department of Highways used a heavy cotton fabric to reinforce the surface of a road they were constructing. The most important characteristic of Geotextiles used in road construction is that they apply stabilization to the road pavement structure, and the heavy cotton fabric used by the South Carolina Department of Highways provided stabilization and proved to reduce cracking and potholes while the cotton fabric remained intact. The problem with geotextiles is that their deterioration compromises the integrity of the construction project they were used on. The cotton used in South Carolina in 1926 did not have the same integrity as geotextiles used today and as it degraded, so did the road.

Widespread use of geotextiles in road construction didn’t begin until the 1960s when the government of the United States began applying them towards several federal projects. As noted by the Geosynthetic Materials Association, “Pavements in the U.S. ?rst incorporated geotextiles beneath roads, parking lots and railroad track ballast in the 1960s. In the early 1970s, we estimate 3 million square yards of geotextiles were used in infrastructure projects. By the 2000s, we estimate more than 300 million square yards were used beneath roads throughout the world. Most state Departments of Transportations (DOT) now have standard specifications for their use in roads (Geosynthetic Materials Association).” One of the projects the U.S. government began experimenting with geotextiles on was the stabilization of logging roads. The geotextile fabric that was used by the U.S. Department of Agriculture was made of woven Saran yarn. Around this time, in the mid 1960s, Europe also began experimenting with different geo-synthetics due to the increase in costs to and declining availability of sand and gravel. After numerous successful implementations, it was clear that geotextiles one play a big part in the future of road construction.

Many road projects in the United States, at both a federal and state level, began implementing the use of geotextiles on projects that they were well suited for. One example that highlights the successful implementation of geotextiles takes place in Minnesota in 1979. Minnesota’s Wright County, located northwest of the Minneapolis and St. Paul metropolitan area, had budget in some road resurfacing projects that traveled through areas of soft swampy soil with layers of peat that ranged from 4-11 feet deep. The Wright County Highway Department was planning for extensive excavation of the unstable muck, but then they decided to consider using engineered geotextile fabric.

Geotextiles had become more popular for use during road construction and it seemed like it would provide a reasonable solution to a lot of the problems the Highway Department was preparing to encounter. Geotextiles were not unheard of since they were popular in erosion control and drainage applications, but the Wright County Highway Department was having some trouble determining which geotextile was the most appropriate for their construction needs. The contractor ended up choosing a fabric that they felt could best handle the muddy environment.

When the Wright County Highway Department began implementing the geotextile they ran into many of the same problems that other construction outfits had ran into. Arguably the biggest problem that they had was that the sub-grade was so soft that it kept shifting beneath the geotextile and, as a result, would shift the geotextile off from its appropriate position. It’s a problem that any construction outfit encounters while working on especially mucky ground. Contractors in Louisiana would encounter similar problems while working on levees and, almost a decade after Minnesota’s Wright County was working on resurfacing their roads, resolved the issue by using geogrid instead of geotextile. Geogrid is more rigid, but is also more costly than geotextile. The Wright County contractor solved their problem with slippage by allowing for a larger overlap to compensate for any shifting of the geotextile. It is essential to have some overlap between sheets of geotextiles to prevent contamination of the imported aggregate by the lower quality soil of the sub-grade, and in many applications the sheets of geotextiles are sewn together for added strength and to prevent slippage.

Category

The largest product category of geo-synthetics is geotextiles. The polymers used to create geotextiles have a significant effect on the category of the product as well as the methods through which it can be stored. Different geotextiles are more suitable towards different applications and construction environments. Depending on what will be required of the geotextile will determine what kind of material the geotextile will be made of and how it will be made. Whether a geotextile is woven or non-woven will affect the pore size of the geotextile and generally determines what applications for which it’s best suited.

Woven

Woven geotextiles have a very uniform pore structure and are consistent in size and spacing throughout the geotextile. A woven geotextile is created by using a large industrial loom from fibers that are either a monofilament string, a multifilament yarn, or flat slit-film. There are two basic weaves: the plain weave and the twill. A plain weave is where the fabric is woven, either tightly or loosely, in an intersecting over-under pattern. The main difference in defining weave style has to do with pore structure as Bhatia and Smith note, “the manufacturing process used to make a geotextile plays a major role in the pore structure of a geotextile. Woven geotextiles have a very uniform pore structure; the pore sizes are regular with little variability throughout the geotextile. Nonwoven geotextiles, on the other hand, are randomly oriented with complex pore geometries over a wide range of pore sizes (Bhatia & Smith, 1996).” The different styles of weaving affect the physical property of the geotextile, ultimately making more-strong as a source of support. Engineers usually weave geotextiles into high flow or low flow textile points. A twill weave is a tighter weave, but that doesn’t mean that it’s pores are smaller than the pores found in a plain weave. The size of a plain weave’s pores can be adjusted depending on the spacing between the parallel fibers while a twill weave is tight, rigid, and consistent.

Knitted

Manufacturing innovations have created an emergent need for knitted geotextiles. This style of geotextile is specifically used for strong support through the use of a polyester yarn. The difference between knitted geotextiles and weaved ones, is that the knitted yarns, or fibers are not interlocking but instead they are knitted together with a binding yarn, and then a reinforcing yarn. Geotextiles that are formed through non woven methods are developed by laying the fibers down in one place and then needle punching them together. This way them fibers naturally hold on to one another. In addition to creating knitted and woven geotextiles, some manufactures also create fibers.

Fibers

Geotextile fibers can be made from naturally occurring fibers, some geotextiles used in erosion applications are often made from coconut fibers. The most common and widely used polymers in geotextiles, and in geosynthetic products, are polypropylene and polyester. Both polypropylene and polyester are reasonably low cost and can fairly easily be manipulated into a variety of geotextile structures. Other materials used to create geotextile fabrics are polyethylene, PVC, and some high quality high-performance materials like Kevlar and, on rare and specific applications, glass. Fibers are made through one of two method, spun bond manufacturing, or carding manufacture. The way the fiber is created dictates the performance of the product being created. Spun bond only uses one type of fiber, while staple fibers uses multiple types of fibers.

Criteria

The conventional process of road construction requires the excavation and then the importation of aggregate to create a uniform base for the road. This is why, “drainage, filtration, separation and reinforcement are the principle functions of geotextile products. In addition to these basic functions, geotextiles have unique properties that can provide effective solutions to many problems in civil engineering (El-Gamal & El-Shafey, 2000).” In civil engineering, specifically when it comes to constructing roadways, one of the most complicated issues engineers face it the process of excavating and importing aggregate. This excavation and importation process takes up a lot of time, money, and energy. Geotextiles have become popular for road construction due to the fact that they significantly reduce the required depth of excavation, especially when constructing a road over a soil of poor quality. Numerous case studies have evaluated the benefits of geotextile use in paving roads.

Case Studies

Duluth, Minnesota Airport Authority —In a paper published in Geotechnical Fabrics Report (August 1999), the performance of a bituminous airport taxiway (Taxiway A) was evaluated after 15 years of use at the Duluth International Airport in Minnesota. As a result of superior performance of the geotextile pavement section, the Duluth Airport Authority reported that funding for the crack sealing of this particular pavement section had been shifted to a another taxiway/runway of the same age that had not been constructed with geotextiles.

Harford County, Maryland—Harford County, a bedroom suburb of Baltimore has many years of experience with the advantages of using geotextiles beneath pavements. County officials report that when they constructed Technology Drive, the primary roadway into the minor league baseball facility, Ripken Stadium, that a separation geotextile was used over a soft sub-grade. After 7 years of performance, the County reported superior performance compared with other roadways of the same age that did not use geotextiles.

In Greenville County, South Carolina, a national conference study published paper on their findings (Geosynthetics’ 1997). They ran a road test study for Greenville County, S.C. which found that through incorporating a separation geotextile in a pavement section, that pavement maintenance obligations decreased by 5-15% annually over a 9-year period.

Application

Geosynthetics are useful and appropriate for a wide variety of construction applications, such firming up soil to provide it with more support and sustainability. Geotextiles are most useful when applied towards road and highway construction. While geotextiles are not as rigid and useful over swampy ground or embankments as a geogrid, geotextiles are strong enough and cost effective enough to provide a solution to a variety of geotechnical problems.

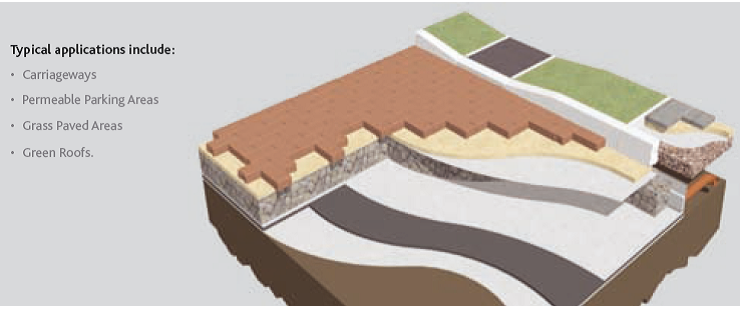

Some of the most common applications of how geotextiles are used include lightweight non-woven geotextiles applied to road surfaces to reduce water ingress and to limit surface cracking, protecting landfills to provide drainage and acting as filtration. Geotextiles are actually being applied to coastal regions to provide filtration but to also act as covers for beaches and port fronts. Ina all cases of geotextile use, the fabrics are implemented in conjunction with soil for the exact purpose of providing additional strength, preventing contamination of fill material, maintaining soil particles while also allowing the passage of water, and forming flexible containment for the protection of coasts.

In road and railways construction solid formation is mandatory. The traditional method of providing a uniform base requires the implementation and exportation of aggregate, but this can be costly. Geotextile can reduce the required depth of excavation allowing civil engineers and constructionists to save money. They can also be used to support aging pavements. Geotextiles are used in a wide range of civil infrastructure like bridge constructions as well to guard against flooding.

In regards to the application of geotextile layers above and below non-porous liners geotextile assist engineers in keeping these areas sustainable while still filtering water through soil. This is extremely beneficial in the construction of road pavement as it keeps the soil below ecologically sound. A geotextile can be applied at different stages of a road pavement structure depending on its desired purpose and what stage of construction the structure is at. The classic use of a geotextile is at the base of a road formation. Geotextiles can be laid on top of an old asphalt road surface or on top of cement or concrete pavement so that resurfacing projects won’t require excessive excavation of old infrastructure. Geotextiles can also reduce or delay the decay of old pavement asphalt by being implemented over cracks and degrading road surfaces before new asphalt is applied. At the same time, geotextiles can also reduce an asphalt pavement’s rutting and low temperature cracking and improve its service life.

Low permeability liners, such as geo-membranes and geosynthetic clay liners are often used in landfills and placing geosynthetic layers above and below these liners prevents puncturing in case where water, or toxic chemicals are built up in the area.

(MrGeosynthetic, 2010)

A high grade highway’s pavement structure is mainly asphalt pavement and cement concrete pavement. These two kinds of mechanical properties of different pavement structures greatly benefit from the appropriate application of geotextiles. The proper and most common placement of a geotextile is at the base of a road formation. Being placed at the base, below the fill aggregate, allows for the greatest benefit to be reaped from using a geotextile. At the base, the geotextile can help separate moisture from the road structure while separating the imported fill aggregate from the lower quality soil.

When resurfacing older roads, especially old rural roads, it is common to do only minor excavation and roll out the geotextile over the old road surface. Many old roads that don’t meet or weren’t built to modern standards server as a good base for geotextiles since geotextiles only require a somewhat level surface free of sharp rocks, trees, and large pits. Older paved and unpaved roads are generally in good enough shape to have a geotextile rolled out over them to serve as a base for construction (Mirafi, 2005)

Even roads that are too degraded for large vehicles or commercial traffic, like portions of the road being resurfaced by Wright County, are still in an acceptable enough condition to be able to serve as a sub-grade for the geotextile and the new road structure being build on top of it.

In a report drafted by the University of Cairo on the performance of geotextiles as a sustainable method of soil and water development in Egypt, it was found that geotextiles excelled at drainage, separation and reinforcement as well as filtration functions. Drainage application or filtration is needed when liquid passes through a surface, such as a soil or sediment property. In the case of geotextiles, it’s found that they are able to retain soil particles on the upstream side of the fabric, while providing a soil filter system similar to the traditional graded aggregate structure on the bottom side (MAL & Tarek, . This is a significant feature of geotextile application that benefits the environment substantially. Especially in the case of Egypt in which the report claims the country has had severe environmental decay due to a need for mitigation of the detrimental and environmentally hazardous chemicals used in modern textile use. The unsuitable application of such textiles has led the country to look for alternatives in which geotextiles may provide a promising option.

Geotextiles offer engineers an alternative building method for coastal protection. When geotextiles are stitched into bags to contains sand they can be used as a building material and can actually prevent sand from being washed away by coastal waters. They can also be used in the sea to enhance marine growth, or beneath the sea to form artificial reefs to enhance aquatic life (Vishnudas , Savenije , Anil & Balan, 2005). Geotextiles are made of fibers or yarns. The Terram Geotextiles Corporation does a good job of breaking down the process of geosynthetic filtration and how geotextiles benefit the environment through the use of permeable pavements that act both as filters and surface structure.

Cost

In the manufacturing of geotextiles, manufacturers consider the function and performance necessary for its particular use, the type of fiber fabric that was used to develop the geotextile, and the polymer from which the fiber originates. All of these factors decide the method through which the geotextile will be manufactured, for example whether it will be woven, knitted, or non-woven (MrGeosynthetic, 2010)

This has a significant influence on how much it will cost.

Costs and cost savings generally vary from project to project. For example, “The cost of the installed separation geotextile is typically less than the cost of 1 inch of base course aggregate; separation geotextiles typically prevent contamination of several inches of base aggregate. Therefore, the bene?ts significantly outweigh the cost of using a separation geotextile in pavements (Geosynthetic Materials Association).” For the Wright County road resurfacing project, which took place in Minnesota in 1979, it was estimated that the use of geotextiles over more traditional methods of excavation and importation of aggregate saved the construction project around $60,000 dollars in excavation costs. Factoring for inflation, the savings in excavation cost alone would be over $190,000 in 2012. Wright County however is one of the more optimal excavation cost saving examples available since the mucky soil was bad enough to require extensive and costly excavation if geotextiles were not going to be implemented, but the soil wasn’t so unstable to the point where geotextiles couldn’t effectively be implemented.

Aside from the variable cost saving qualities of geotextiles during construction, there is also the added benefit of cost savings incurred by extending the life expectancy of the road. Geotextiles help mitigate some of the wear and tear associated seasonal and environmental changes. Over time the underlying soil can contaminate the imported aggregate, but geotextiles increases the durability of a road structure by either mitigating or, in most cases, preventing contamination. If a proper drainage system has been designed then geotextiles can assist in allowing moisture to drain away from the road, which often extends the life of any soil based structure, and geotextiles can be used to seal and reinforce the surface of aging pavements.

There is also the global consumption factor of geotextiles use, as Fisher notes, “The global production of textiles used in geotextile, construction and other civil engineering applications is around 1.38 million tons per year –12.6% of total technical textile consumption– and valued at US$5.25 billion. Annual average growth during the 2000-05 period was estimated at 4.3% by volume for construction textiles and 7.3% for geotextile/civil engineering products (Fisher, 2006).” This potential expansion of geotextile use worldwide for civil engineering projects makes the manufacturing of geotextiles a lucrative and environmentally sound market. It also means big business for big business, as there is always going to be a global market for roadways and construction.

In a case report published by the Virginia Transportation Research Council, it was found that using a simple cost perspective, material and installation costs of common geotextiles at an amount of about $6,000/lane-mile proved to be a much more affordable durable and long lasting alternative to the needed interim rehabilitation and repair costs of $40,000/lane-mile or more for an equivalent total service life of other options (Hossain & Schmidt, 2009). Despite the fact that unit cost information for geotextiles is readily available (approximately $0.66/ yd2 including delivery), Hossain and Schmidt found that there are variable costs involved in the implementation and installation of new geotextile protocols in a construction project. Although geotextile installation is relatively simple, “it is expected that special handling requirements would add an installation premium to the cost of construction with geotextile because aggregate must be back-dumped, instead of spread using a conventional spreader box, to avoid damage to the textile (Hossain & Schmidt, 2009).”

This suggests all is not perfect when it comes to implementing geotextile use as there are always some unexpected variable costs.

Conclusion

Geotextiles excel in their contribution towards pavement construction. They are an economic, environmentally conscious alternative to contemporary textiles. They also represent a growing trend in construction that can mean big business for manufacturers looking to supply civil engineering and construction contractors with alternative roadway paving materials.

Work cited

Bhatia , S. K., & Smith, J. L. (1996). Geotextile characterization and poresize distribution: Part i. a review of manufacturing processes. (1 ed., Vol. 3, pp. 85-105). Geosynthetics International. Retrieved from http://www.geosyntheticssociety.org/Resources/Archive/GI/src/V3I1/GI-V3-N1-Paper6.pdf

El-Gamal, M. A. L., & El-Shafey, T. M. (2000).Performance of drainage geotextiles for sustainable development of soil and water resources in egypt. Retrieved from http://www.virtualacademia.com/pdf/eng1_13.pdf

Elton, D. J., & Barrato Patawaran, M. A. (2005).Mechanically stabilized earth (mse) reinforcement tensile strength from tests of geotextile reinforced soil. Auburn University. Retrieved from http://www.eng.auburn.edu/files/file805.pdf

Fisher, G. (2006). Rising use of geotextiles as civil engineers see cost benefits. Journal for Asia on Textile & Apparel, Retrieved from http://www.adsaleata.com/Publicity/ePub/lang-eng/article-871/asid-76/Printing.aspx

Geosynthetic Materials Association. (n.d.). Geotextiles enhance road performance. Retrieved from https://secure.ifai.com/gmanow.com/repository/8/2313/geotextiles_road_performance.pdf

Hossain, M. S., & Schmidt, B. N. Virginia Department of Transportation , Virginia Transportation Research Council (2009). Benefits of using geotextile between subgrade soil and base course aggregate in low-volume roads in virginia. Retrieved from website: http://www.virginiadot.org/vtrc/main/online_reports/pdf/10-r1.pdf

Mirafi. (2005). Case study: Lousiana levee. Mirafacts,2(2), Retrieved from http://www.tencate.com/TenCate/Geosynthetics/documents/Mirafacts/levee.pdf

MrGeosynthetic. (2010). Geotextiles lecture [Web]. Retrieved from http://vimeo.com/15092219

Terram. (n.d.). Geotextiles. Retrieved from http://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&cad=rja&sqi=2&ved=0CEAQFjAA&url=http://www.terram.com/download-file.php?fid=21&ei=EIK-UOXSKYiK8QSisYGYCg&usg=AFQjCNFne6JilIDSTsEc2C4k4hyy4biAtw&sig2=TEEO49uj7HahedTYZ–9bw

Vishnudas , S., Savenije , H. H. G., Anil , K. R., & Balan, K. (2005). Experimental study using coir geotextiles in watershed management.Hydrology and Earth System Sciences Discussions, 2, 2327-2348. doi: 2, 2327–2348, 2005

Time is precious

don’t waste it!

Plagiarism-free

guarantee

Privacy

guarantee

Secure

checkout

Money back

guarantee