All papers examples

All papers examples

Disciplines

- MLA

- APA

- Master's

- Undergraduate

- High School

- PhD

- Harvard

- Biology

- Art

- Drama

- Movies

- Theatre

- Painting

- Music

- Architecture

- Dance

- Design

- History

- American History

- Asian History

- Literature

- Antique Literature

- American Literature

- Asian Literature

- Classic English Literature

- World Literature

- Creative Writing

- English

- Linguistics

- Law

- Criminal Justice

- Legal Issues

- Ethics

- Philosophy

- Religion

- Theology

- Anthropology

- Archaeology

- Economics

- Tourism

- Political Science

- World Affairs

- Psychology

- Sociology

- African-American Studies

- East European Studies

- Latin-American Studies

- Native-American Studies

- West European Studies

- Family and Consumer Science

- Social Issues

- Women and Gender Studies

- Social Work

- Natural Sciences

- Anatomy

- Zoology

- Ecology

- Chemistry

- Pharmacology

- Earth science

- Geography

- Geology

- Astronomy

- Physics

- Agriculture

- Agricultural Studies

- Computer Science

- Internet

- IT Management

- Web Design

- Mathematics

- Business

- Accounting

- Finance

- Investments

- Logistics

- Trade

- Management

- Marketing

- Engineering and Technology

- Engineering

- Technology

- Aeronautics

- Aviation

- Medicine and Health

- Alternative Medicine

- Healthcare

- Nursing

- Nutrition

- Communications and Media

- Advertising

- Communication Strategies

- Journalism

- Public Relations

- Education

- Educational Theories

- Pedagogy

- Teacher's Career

- Statistics

- Chicago/Turabian

- Nature

- Company Analysis

- Sport

- Paintings

- E-commerce

- Holocaust

- Education Theories

- Fashion

- Shakespeare

- Canadian Studies

- Science

- Food Safety

- Relation of Global Warming and Extreme Weather Condition

Paper Types

- Movie Review

- Essay

- Admission Essay

- Annotated Bibliography

- Application Essay

- Article Critique

- Article Review

- Article Writing

- Assessment

- Book Review

- Business Plan

- Business Proposal

- Capstone Project

- Case Study

- Coursework

- Cover Letter

- Creative Essay

- Dissertation

- Dissertation - Abstract

- Dissertation - Conclusion

- Dissertation - Discussion

- Dissertation - Hypothesis

- Dissertation - Introduction

- Dissertation - Literature

- Dissertation - Methodology

- Dissertation - Results

- GCSE Coursework

- Grant Proposal

- Admission Essay

- Annotated Bibliography

- Application Essay

- Article

- Article Critique

- Article Review

- Article Writing

- Assessment

- Book Review

- Business Plan

- Business Proposal

- Capstone Project

- Case Study

- Coursework

- Cover Letter

- Creative Essay

- Dissertation

- Dissertation - Abstract

- Dissertation - Conclusion

- Dissertation - Discussion

- Dissertation - Hypothesis

- Dissertation - Introduction

- Dissertation - Literature

- Dissertation - Methodology

- Dissertation - Results

- Essay

- GCSE Coursework

- Grant Proposal

- Interview

- Lab Report

- Literature Review

- Marketing Plan

- Math Problem

- Movie Analysis

- Movie Review

- Multiple Choice Quiz

- Online Quiz

- Outline

- Personal Statement

- Poem

- Power Point Presentation

- Power Point Presentation With Speaker Notes

- Questionnaire

- Quiz

- Reaction Paper

- Research Paper

- Research Proposal

- Resume

- Speech

- Statistics problem

- SWOT analysis

- Term Paper

- Thesis Paper

- Accounting

- Advertising

- Aeronautics

- African-American Studies

- Agricultural Studies

- Agriculture

- Alternative Medicine

- American History

- American Literature

- Anatomy

- Anthropology

- Antique Literature

- APA

- Archaeology

- Architecture

- Art

- Asian History

- Asian Literature

- Astronomy

- Aviation

- Biology

- Business

- Canadian Studies

- Chemistry

- Chicago/Turabian

- Classic English Literature

- Communication Strategies

- Communications and Media

- Company Analysis

- Computer Science

- Creative Writing

- Criminal Justice

- Dance

- Design

- Drama

- E-commerce

- Earth science

- East European Studies

- Ecology

- Economics

- Education

- Education Theories

- Educational Theories

- Engineering

- Engineering and Technology

- English

- Ethics

- Family and Consumer Science

- Fashion

- Finance

- Food Safety

- Geography

- Geology

- Harvard

- Healthcare

- High School

- History

- Holocaust

- Internet

- Investments

- IT Management

- Journalism

- Latin-American Studies

- Law

- Legal Issues

- Linguistics

- Literature

- Logistics

- Management

- Marketing

- Master's

- Mathematics

- Medicine and Health

- MLA

- Movies

- Music

- Native-American Studies

- Natural Sciences

- Nature

- Nursing

- Nutrition

- Painting

- Paintings

- Pedagogy

- Pharmacology

- PhD

- Philosophy

- Physics

- Political Science

- Psychology

- Public Relations

- Relation of Global Warming and Extreme Weather Condition

- Religion

- Science

- Shakespeare

- Social Issues

- Social Work

- Sociology

- Sport

- Statistics

- Teacher's Career

- Technology

- Theatre

- Theology

- Tourism

- Trade

- Undergraduate

- Web Design

- West European Studies

- Women and Gender Studies

- World Affairs

- World Literature

- Zoology

Microstructures of Different Types of Cast Iron and Steel, Research Paper Example

Hire a Writer for Custom Research Paper

Use 10% Off Discount: "custom10" in 1 Click 👇

You are free to use it as an inspiration or a source for your own work.

Cast Iron

As generally understood that during the reduction in the blast furnace, cast iron possesses all the carbon and it cannot take temper and also cannot be welded or cast. In the production of cast iron, other imparities or other ores that has obtained from the fuel can be used. For white and Gray, cast iron combines at 2075 F and 2230 F respectively. It is not an alloy or a simple metal but it is a collection of compounds mix together chemically and mechanically. It transforms into a material of different qualities altogether is there are any changes in the quantities of the elements and compounds that it’s made up of, in the conditions attending its production in the blast-furnace, in its solidification or re-melting.

Any iron that cannot be classes with steel due to its high levels of carbon is known as cast iron. In various furnace yards, cast iron is divided into over twenty grades on the account of its’ variety of appearances of its exterior surface or of its fracture. When sold, the chemical makeup of each run of iron might differ from other accounts of diffusion of elements that’s unequal.

Microstructure in Cast Irons

Gray Cast Iron

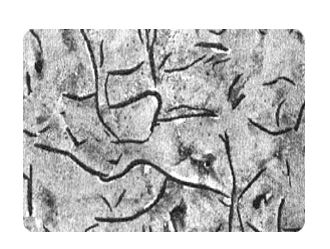

Fig: 1

The specific microstructure characteristic of gray cast iron is the existence of graphite in the form of flakes, as shown in fig:1. In this micrograph, the flakes (dark gray) are encircled by a array of pearlite. The array of an as-cast gray iron can also include of 100% ferrite, 100% pearlite, or numerous mixtures of pearlite and ferrite. In addition, the matrixes of heat treated gray iron incorporate other transformation products, such as martensite and bainite. In the pearlitic gray iron shown in the fig: 1, the graphite flakes are extremely long. Gray cast irons can have flakes of numerous lengths and of different morphologies. Gray cast iron typically consists between 1 and 3% Si, because silicon encourages the structure of graphite, that is, silicon is a graphitize. In Fig: 1, the graphite flakes appear separated, but if observed in three dimensions, the flakes would be interrelated. The three-dimensional array would involve what is called a cell.

The flakes impart a degree of brittleness to this form of cast iron. Therefore, gray cast iron is usually not used in applications where critical parts are subjected to impact or folding stresses. However the flakes also conduct a degree of damping capacity. Gray cast iron is very useful as frames or bases in all kinds of heavy machinery. Gray iron, because of the soft graphite flakes, is easily machinable.

White Cast iron

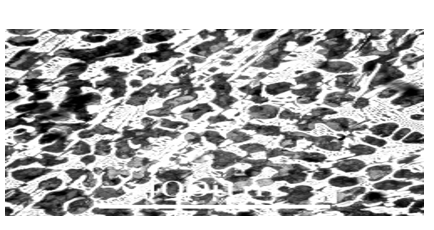

Fig: 2

As seen in Fig: 2, the microstructure of white cast iron is completely different from gray cast iron. In this microstructure, there are no graphite flakes present. The bigger, dark gray, rounded areas in fig: 2 include of pearlite. “The arranged array of these rounded areas is an outcome of the original dendrite structure that created during solidatification. Each large, rounded patch of pearlite created between a branch and arm of a dendrite” (Scott, 1991). The white continuous phase in fig.2 is commentating, and the areas that contain the small, rounded pools are the mixture constituent called ledeburite. Because of the large amount of the continuous cementite phase, white cast irons are usually brittle, very hard, and hard to machine. In fact, the high hardness makes white cast iron beneficial for applications requiring wear and abrasion resistance, for example, rolls and ore/rock crushing machinery.

Mottled Cast Iron

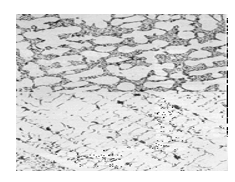

Fig. 3

Whenever a cast iron includes of a mixture of gray and white iron, the cast iron is called mottled cast iron, because of its mottled or speckled presentation in a fractured surface. Fig. 3 shows an example of the microstructure of mottled iron. Note the existence of graphite flakes in a matrix of pearlite, that is, the gray iron microstructure, adjoining to a continuous network of cementite, pools of ledeburite, and rounded areas of pearlite, that is, the white iron microstructure.

Malleable Cast Iron

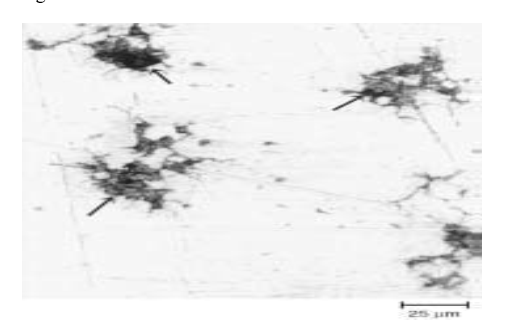

Malleable cast iron cannot be generated as -cast and is produced only by heat managing white cast iron at temperatures and times that are adequate to disintegrate the cementite into carbon. These heat treatment cycles happen to be about 870 to 925 C for 15 to 24 hours. The diagnostic microstructure of malleable iron is shown in the fig: 4. In this illustration, the unusual shaped dark areas are called “temper carbon” a form of graphite, and the array is pearlite.

Graphite is the consistent form of carbon in cast irons and steels, whereas cementite is meta stable, which means that with adequate time and temperature, cementite will potentially revert to graphite. Because of the rounded form of the temper carbon, the properties of malleable iron are somewhat similar to ductile cast iron.

Fig: 4

Microstructure of Steel

“The corrosion resistance of the stainless steels is due primarily to the existence of chromium. Even though comparatively small additions of this element, of the order of 5% absolutely produce improvements, at least 10.5% chromium is needed to possess passiveness” (Tverberg, 2001). There’s a variety of stainless steels, all of which have iron as their base and a minimum of 10.5% of chromium. Other elements, such as molybdenum, nickel, niobium, titanium, copper and nitrogen may also be included in their compositions. The stainless steels may also include alloying additions whose major role is finalized during melting and refining, like manganese and silicon, and others which enable machining, such as sulfur and selenium. There are various kinds of steel.

Ferritic and martensitic stainless steels

Chromium is the essential alloying element. The high chromium levels, that contains molybdenum and sometimes nickel to benefit toughness, are often referred to as “super ferritic” stainless steels.

Microstructure of Ferritic stainless steels

The ferritic stainless steels have low carbon contents, usually less than .07%. they do not therefore show considerable solidifying after heat treatment. Although the ferritic stainless steels can usually be welded by all the standard processes, the following methods should be taken:

- Limited welding power, to decrease malleability losses due to grain growth in the heat affected zone.

- Hydrogen and nitrogen must not be included to the argon, since they reduce the ductility of the weld.

- Pre and postheating are not important for fully ferritic grades.

- For semiferritic steels, postweld treatment at 750 -880 C will restore the ductility of the joint.

- Titanium or niobium stable grades are to be recommended to avoid intergranular corrosion problems due to the precipitation of chromium carbides at grain boundaries.

Martensitic stainless steels

The martensitic stainless steels is going to have higher carbon contents than the ferritic grades. Their mechanical energy can be considerabley developed by extinction from the austenite field. Like ferrite, the martensite structure is magnetic at room temperature. In the annealed or tempered conditions, these grades are not brittle, but in the as-quenched state they are practically under formable. They are difficult to weld and find few applications in seawater.

Microstructure of Austentic stainless steels

“The main alloying elements are chromium and nickel. In a the same way to the super ferritic alloys, austentitic grades with a total of more than 45% of alloying additions are known as “super austenitic” stainless steels. The most commonly used stainless steels are the austenitic grades, of which types 302 and 304 are the most desirable” (Tverberg, 2001). These grades contain 16% or more chromium, a ferrite-stablizing element, and appropriate austenite-stabilizing elements, such as carbon, nitrogen, nickel, and manganese, to establish austenite stable at room temperature.

References

Scott, D. A., (1991), Metallography and Microstructure of Ancient and historic metals .

Retrieved from http://www.getty.edu/conservation/publications_resources/pdf_publications/metallography.pdf

Tverberg, J. C.; (2001), Stainless Steel in the Brewery, volume 38, number 2, pg. 67-82

Stuck with your Research Paper?

Get in touch with one of our experts for instant help!

Time is precious

don’t waste it!

writing help!

Plagiarism-free

guarantee

Privacy

guarantee

Secure

checkout

Money back

guarantee