Technology Innovation and Commercialization, Research Paper Example

Application of 3D4D in construction project

Introduction

This study provides the modeling guidelines on the 3D/4D for the construction experts with interest in pursuing delivery of this kind of innovative project. It is through these modeling guidelines that the researcher gains unique experience on model developers and integrators in the construction projects. There is also outlining of the implementation process based on the lessons learnt from some few building and construction projects that have already practiced it.

The study also discusses in detail the technical and procedural matters tackled by teams of the project during their undertakings. Organizational issues are also confronted in this innovative type of working. Moreover, the research explains different and various approaches applied to assemble the work of this project on leverage level of these technologies. Modeling requirements for the implementation of these projects, advantages, challenges, recommendations and conclusions for the technology process and its impacts on the outcome of the project are also discussed in the research.

Literature review

The perspective of 3D4D modeling technology

In the recent years, some meaningful improvements have been seen on the available models, designs and tools for construction projects using the technologies of 3D and 4D (Tatum & Korman, 2000). The current available 3D and 4D modeling tools have shown great significance in offering pre-defined items that are used in the facilitation of the construction development, routing and as well in the linkage of building systems. The items provide significant mechanisms for conflict detection that are helpful in identifying physical interferences automatically that may exist between components.

The performance impacts of 3D and 4D on construction projects

The 3D4D modeling tools connect the scope of the particular project with the schedules of construction in order to simulate the process of the construction graphically. Several efforts by various research scientists have highly discussed and explored the potential ability of the tools to effectively improve the development of the design coordination as well as the execution of construction projects (Whyte, Bouchlaghem & Thorpe, 2000). However, implementation of 3D4D modeling on projects that show actual capacity in environments of multi-disciplinary and multi organizational impacts proves to be a complex process that needs highly coordinated efforts (Tatum & Korman, 2000). However, there are adequate varieties of technical and as well procedural matters that need to be elaborated more and that also have potential of explaining their limited use.

In addition, there is no adequate research work that critiques these modeling tools in the perspective of project teamwork on projects with actual plans. Therefore, without the demonstration of any available benefits that provide implementation guidelines, it is not possible for construction practitioners to begin investments on the resources essential for adoption of these modeling technologies (Whyte, Bouchlaghem & Thorpe, 2000).

3D and 4D have practically been applied on various projects especially on the construction field. Past research, work has come up with efforts that compile some case studies that indicate assessment of the benefits as well as the limitations of 3D4D modeling tools and their effects on the performance of the construction projects. However, some scholars argue on the efficient functionality of the 3D and 4D modeling technologies and the needs of the construction industry (Tatum & Korman, 2000).

Application of these modeling tools has for specific purposes been done as constructability analysis. 3D/4D tools have been faced by various benefits and challenges in their application particularly to the effective coordination of electrical, plumbing, civil, mechanical and fire protection systems on complicated projects. In current years, there have been increased investigations on the techniques and capability of interaction for 3D/4D models applying immersive techniques (Ganah, Bouchlaghem & Anumba, 2005). The establishment of these models has been widely used in resolving challenges facing the construction design.

The project work demonstrates despite a room for expansion, 3D/4D technologies have been of much importance to the development of effective coordinated and constructible models, designs and as well as construction sequences. The models have been helpful in the identification of design conflicts, errors of building designs, constraints of sequencing, access matters, details concerning fabrication methods and available procurement constraints that have potential of affecting effective delivery of the project process. The application of these stools is significant in minimization of any risks and instead attracts construction of quality projects. These technologies have become popular among several professional of different fields and it is expected in the coming years they will be common in the market place as the sector tries to cope with certainty of the stiff market labor (Tatum & Korman, 2000).

3D/4D technologies have remarkable effects on execution of projects. These includes abolition of field obstructions, less time in reworking, high increase of productivity, few requests on project’s information, few change of project’s orders, less costs on the expansion and growth of the project and reduces time from commencement of the construction project to facility turnover.

Scope and organization of the project

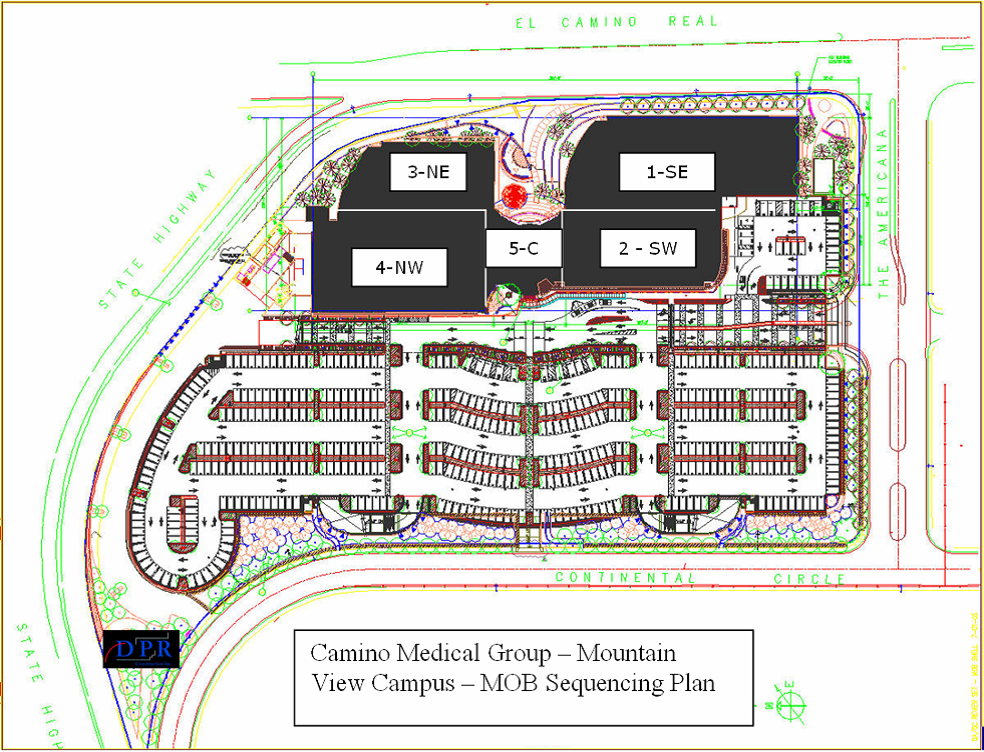

The scope and organization of the project with application of the 3D and 4D technologies is discussed using two company projects that effectively developed and implemented these technologies to certain degrees of their construction and design process. These companies are Camino medical center located in California’s Mountain View and Sequus Pharmaceuticals Pilot Plant Facility located in Menlo Park.

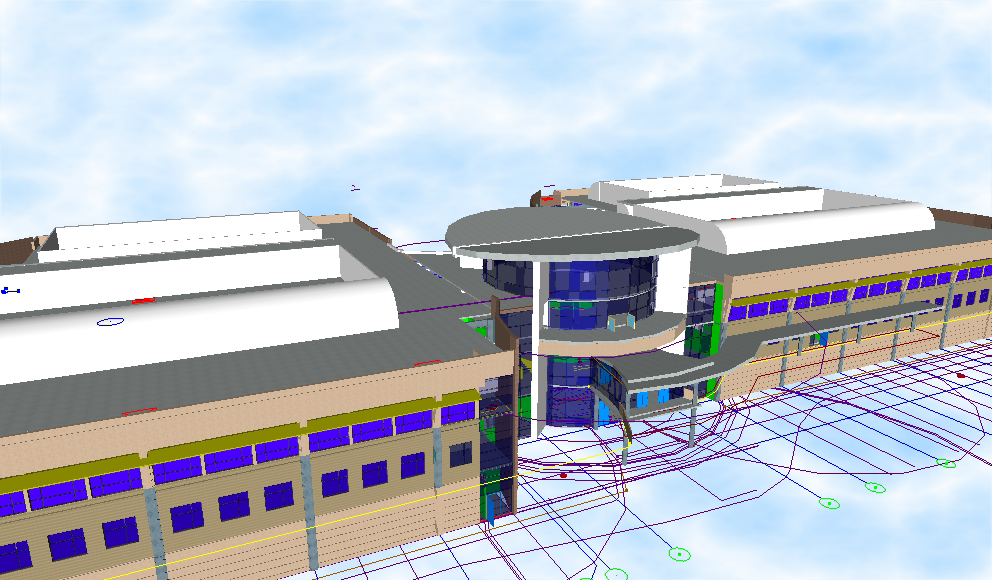

FIG. 1: 3D4D rendering of the three-storey medical office building for the Camino Medical Group Project in Mountain View, California.

The teamwork of this project including architects, engineers, general contractor, subcontractors and the owner effectively applied the use of 3D/4D collaboration tools and coordination. This was guided by inclusion of 3D4D models production with objects of parametric and compatibility of the available software components with software of design reviews (Barton, 1983).

The model was provided and supervised by the architecture responsible for architectural designs and in charge of the structural scope of work. The design of the project was unique in the fact that it was supervised with the use of process delivery of lean project. The goal of the project was to ensure elimination of any available negative iterations leading to reduction of the cycling time by the use of 3D/4D modeling technologies developed by the project’s construction team to coordinate mechanical, plumbing, engineering and fabrication process (Whyte, Bouchlaghem & Thorpe, 2000).

On the other hand, the scope of the Sequus project was construction of pilot plant facility for pharmaceuticals.

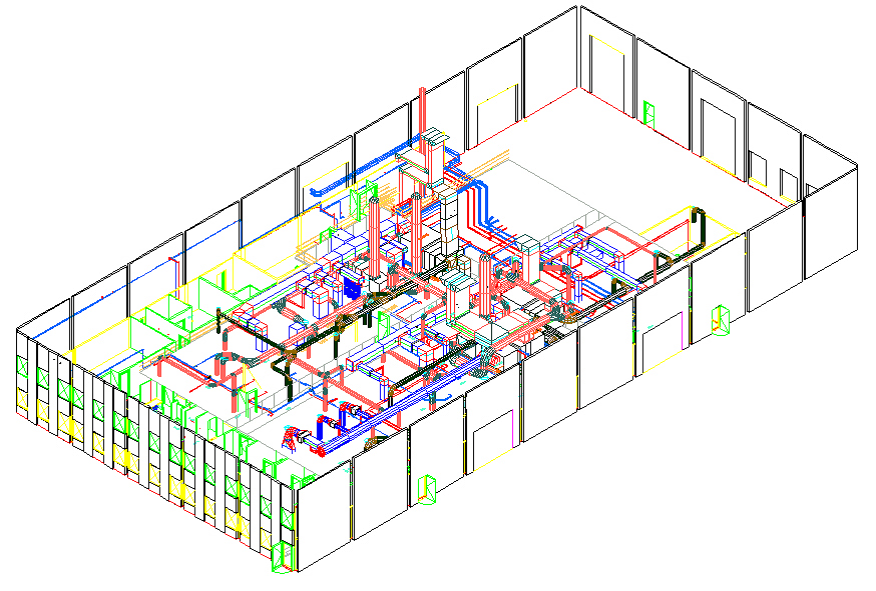

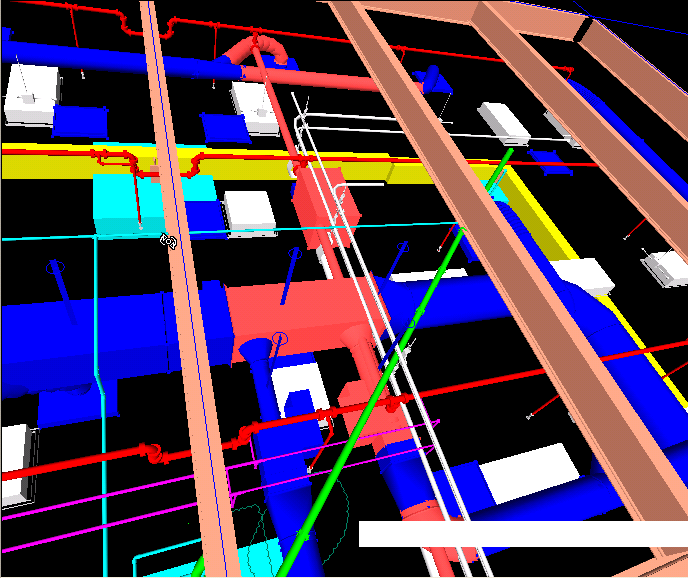

FIG. 2: Integrated 3D4D Model of the Sequus Pharmaceuticals Pilot Plant in Menlo Park, California.

3D/4D design coordination

In situations whereby there is a complex building project, the coordination of building system becomes a challenging and critical task. This is because it requires more detailed configuration of several building systems that effectively complies with construction, design and operations of the project (Tatum & Korman, 2000). The work should involve contractors who have specialized in the field in order to provide effective coordination of MEP systems including checking of clearances, details of fabrication, locations of installations and route identification.

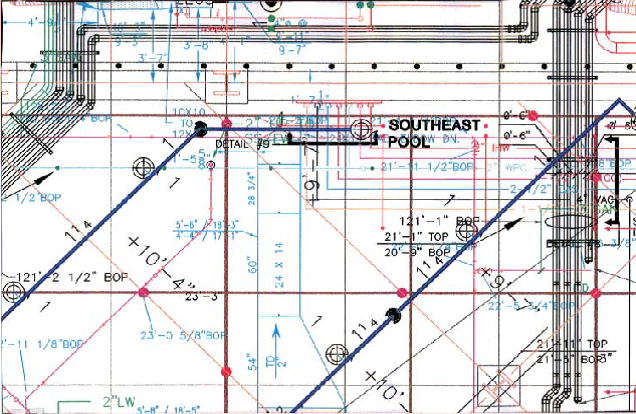

Comparability of 3D/4D with 2D

The 2D design was in the past centuries widely applied by various construction projects. Nowadays the design has been overtaken by 3D and 4D modeling technologies (Staub & Fischer, 2001). 2D modeling technology starts with the design as well as the preliminary routing of the particular completion of the building systems project. Some usual constraints are encountered and that have potential ability of determining the system routing, structure of the corridors, firewalls, shear walls. Other systems determined include the equipment locations as well as the ceiling types and interstitial spaces (Tatum & Korman, 2000).

The main responsibility of each specialty group in the building project is to channel their systems to their potential advantage. This is due to constraints that may have been reflected in the preliminary drawings of the project. This widely includes reduction of branch lengths as well as several numbers of fittings and routing closes for the supporting points. In 2D models, the piping system is likely to be sized at the level of preliminary drawings. However, the fire protection and electrical stages are not sized (Staub & Fischer, 2001). Nevertheless, there are few systems of buildings that are scale-drawn while others are line-drawn depending on the references to their component sizes.

FIG. 3: Typical view n the perspective of MEP systems coordinated in a 2D paper-based process.

3D and 4D coordination process

The significant movement from the 2D to 3D/4D design is and has been a complex process requiring effective and well coordinated efforts to equalize the advantages of the 3D models (Koo & Fischer, 2000). The major steps that effectively explain the coordination process include

- Identification of the effective application for the models

- Identification of the meaningful requirements for the modeling process

- Establishment of the best protocol for drawing

- Establishment of the process relating to any conflict resolutions

- Establishment and development of best protocol that addresses questions on the coordination design

- Effective development of disciplined and specific 3D/4D modeling technologies

- Integration of specific 3D and 4D modeling technologies

- Identification of available conflicts between the system and the components

- Development of effective solutions for identified conflicts

Documenting of existing conflicts and their potential solutions

In the stage of identifying modeling requirements, it is necessary to provide creation of a schedule that indicates identification of major activities of modeling. The schedule is significant in specifying the time when the models require creating, coordinating, updating and approving. In the coordination part, the conflicts are identified while in the updating stage, the conflicts are resolved (Ganah, Bouchlaghem & Anumba, 2005).

The approval stage indicates that the models are ready for fabrication. These landmarks are incorporated in the schedules of construction and coordination process is provided together with installation activities.

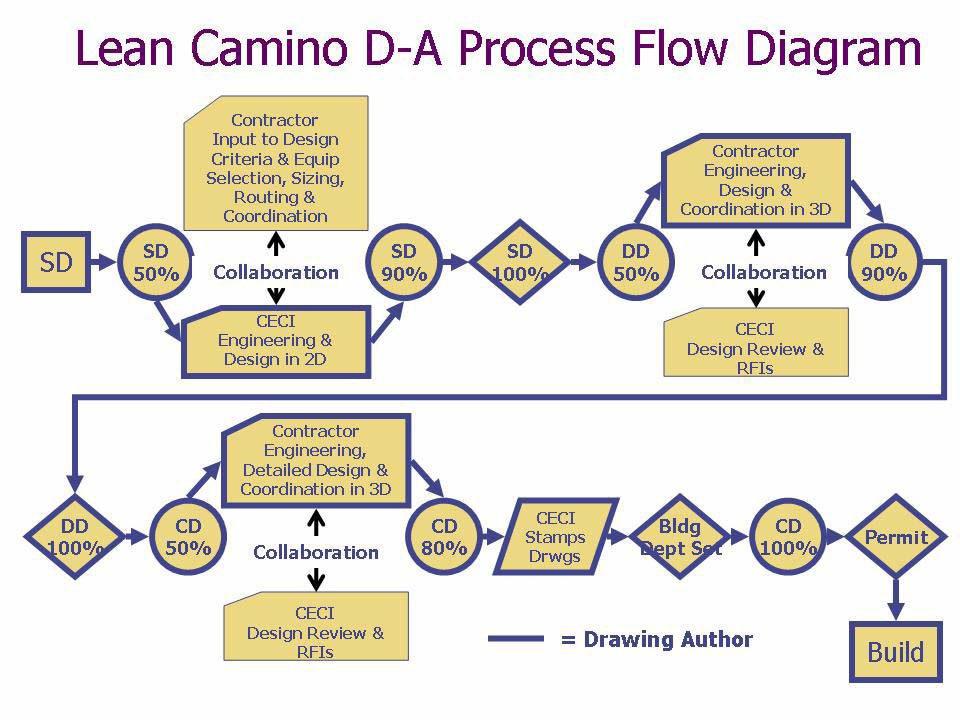

FIG. 5: Flow chart representing design coordination process established on the Camino Project.

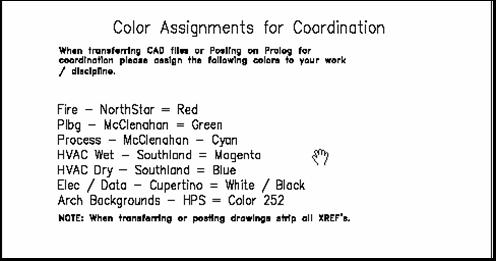

In the establishment of the drawing protocol, file naming convention, version controls, layering convention, color schemes and project reference points. In file naming convention, the file is supposed to communicate the company responsible for creation of the 3D and 4D modeling technology (Tatum & Korman, 2000). The scope and the version of the models should also be communicated. In the above example of Camino Project, the application was on the file naming convention but with the subcontractor’s initials been appended to the drawing. This sis indicated as “M211A_SI.dwg”. This is file name communicating the following; M= Mechanical, 2=HVAC, 1=1st fl, 1=1st Quadrant, A= Area and as well SI= Southland Industries.

In the part of color schemes, there should be a facilitation of visual communication on various scopes of design work. This is shown in Fig. 6 developed from Camino project. It shows how colors are applied for different systems in different companies.

FIG. 6: Color Scheme applied on the Camino Project for 3D 4D coordination.

In the step of developing a protocol that effectively addresses design questions, there is a need for a clear mechanism for the subcontractors as well as detailers working on the model development to come up with questions that relates to the design of the project. These questions should have potential of resolving some complex issues that may have risen up specifically on the fast-tracking projects. When applying the models of 3D and 4D technologies, normal RFI processes are not enough mainly because of the unnecessary time lagging for solution of the complex issues (Whyte, Bouchlaghem & Thorpe, 2000).

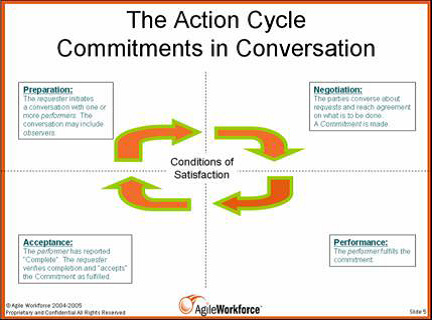

From the above example of Camino Project where web-based system known as commitment manager was used, the project building team and the detailers are able to directly pose questions to the suitable members of the design team instead of channeling those questions via the general contractor. Therefore, this indicates that some valuable time is saved here in trying to solve the matter.

FIG. 8: Screenshot of the Commitment Manager Action Cycle being applied for making requests and answering questions on the Camino Project.

In the step of identifying available conflicts between the system and the components, there is need for allocation of enough time. This is because of the fact that this process tries to identify hard conflicts or physical interferences that exist between the components as well as soft conflicts or interferences between components of the design and available access spaces and as well violation of clearances (Staub & Fischer, 2001). The identification of hard conflicts can either be identified automatically or manually. This depends on particular software that may have been utilized in the project.

Fig. 9 indicates hard conflict been identified automatically between fire sprinkler pipe and supply duct.

FIG. 9b: Hard conflict existing between the Fire Sprinkler Pipe and the Supply Duct that was automatically identified Navisworks Clash Detective on the Camino Project.

Benefits of the 3D and 4D models

- It enables majority of design conflicts to be identified in prior to building and construction. This is through modeling of the models electronically and at the same ttime integrating the models, performing design coordination and as well constructability analysis on accurate and clear representation of the project designs.

- Improvement of the productivity is effectively achieved. This is because design conflicts will have been identified and resolved before construction process therefore ensuring much more productive and efficient process of installations. Several mechanical systems are also able to be fabricated directly from 3D and 4D modeling technologies.

- Less Rework is achieved due to elimination of MEP coordination process before construction process.

- There are increased opportunities for Pre-fabrication systems. This is through better provision of efficient chances of pre-fabricating materials in the market environments through modeling and coordination of thee MEP and fabrication process systems sin 3D and 4D models.

- Fewer requests on the project’s information due to identification and resolution of the conflicts

- Fewer change orders is observed due to the factor of ‘rework’. This is because reworking is perceived by many experts as the major cause of several change orders that may be experienced in the process of construction.

- Designing of errors is easy to be identified before the construction process

- There is ability of building various systems with less and skilled labor personnel

- Safety performance is highly improved as well as achievement of better cost controls.

Establishment of workflow and breakdown in a 3D/4D system

The creation of 3D and 4D modeling technologies requires identification of work breakdown and its flow process. This process also requires involvement of the subcontractors and any other personnel involve in the planning of the design work. The 3D and 4D model is commonly used for coordination of the mechanical, piping and electrical processes in connection to mechanical platform and as well equipment installation (Koo & Fischer, 2000).

FIG.14: The sequence plan for the Camino Project indicaing work proceeding clockwise from the southeast corner (1-SE) and finishing in the center (5-C).

Reorganization of the 3D/4D models is significant since it tries to represent the perspective of the design. This in turn represents the perspective of the construction (Heesom & Mahdjoubi, 2004). The perspective of the design involves organization of the pipes by the system while construction perspective involves organization of the pipes by both construction zones and pipe sizes.

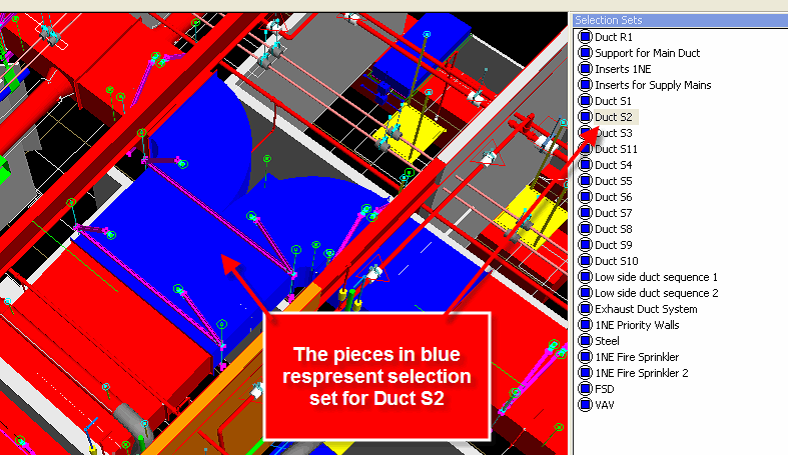

Fig. 15 indicates the selection of project sets for mechanical work. Indication of Duct S2 is highlighted in blue. This is a model with mixture of small and thin duct pieces. However, the installation of the duct elements highly depends on pre-fabricated assembly.

FIG. 15: Selection Sets developd by use of Navisworks Timeliner representing groupings of 3D objects.

Recommendations

Some of the significant recommendations prior to development of the 3D/4D modeling technologies on future construction projects include:

- Determination of the main purposes for the 3D/4D models in the dominating levels of the work schedule

- Setting up 3D4D facilitation that helps in reduction of necessary efforts of reorganizing CAD models in the representation of construction perspectives

- The projected life of the 3D4D information is in most cases limited therefore; there is a need of keeping the modeling technologies up to date.

- In some cases, the 3D4D modeling technology may not be significant in automatically evaluating the existing feasibility of the proposed project schedules. It can also fail to identify the potential and existing conflicts and as well any available problems. Therefore, it is necessary to identify these problems and conflicts manually by use of current 3D4D modeling tools.

In summary, 3D4D modeling tools are very useful to the construction project teams in the organization and coordination of construction disciplines. The models also help in the communication of project schedules more efficiently and help in identifying of constructability matters prior to development of the design (Barton, 1983). There are however, some limitations relevant to attempts necessary for setting up CAD as well as design schedule models. The limitations also extend to potential ability of 3D4D modeling systems dealing with the current design and project schedule changes. The lack and inadequate automated analysis of 3D4D tools is another big challenge.

Conclusions

This research study gives guidelines that are useful to the construction experts in implementing 3D4D modeling technologies on their work projects (Ganah, Bouchlaghem & Anumba, 2005). These guidelines are helpful in overcoming the technical and procedural challenges that serve as major barriers to the adoption of the modeling technologies. However, 3D4D technologies serve as important impacts when it comes to execution of construction projects. These significant benefits include identification of design conflicts, errors of building designs, constraints of sequencing, access matters, details concerning fabrication methods and available procurement constraints that have potential of affecting effective delivery of the project process. The application of these stools is significant in minimization of any risks and instead attracts construction of quality projects.

Effective capitalization of the 3D4D significant benefits, construction facilitators need to promote development of new skills and efficiently ensure implementation of organizational changes (Akinci, Tantisevi & Ergen, 2003). The project owners are supposed to bring in skilled personnel early in the work project. Designers, on their part are supposed to put their focus on the overall design of the project and ensure coordination of tasks. Sub contractors should have knowledge on the design software. This is because of their capacity to the performance of their tasks that include providing detailed project designs and addressing the issues surrounding coordination prior to development of the designs when working closely with architects and engineers.

General contractors are responsible for ensuring manipulation of the 3D4D modeling technologies as well as working closely with all other specialty teams of the project to provide input guidance on the process of modeling these designs in order for CAD tools to become usable or applicable to the constructors.

Bibliography

Akinci, B. Tantisevi, K., & Ergen, E. (2003). Assessment of the capabilities of a commercial 4D CAD system to visualize equipment space requirements on construction sites. Construction Research Congress, Honolulu,HI, 989-995.

Barton P. (1983). Building services integration. E & FN Spon, London.

Ganah, A., Bouchlaghem, N. & Anumba, C. (2005). VISCON: Computer visualization support for constructability. Journal of Information Technology in Construction: Special Issue: From 3D to nD Modelling, Vol 10, 69-83. (Available at www.itcon.org).

Heesom, D., & Mahdjoubi, L. (2004). Trends of 4D CAD applications for construction planning. Construction Management and Economics, 22(2), 171-182.

Koo B. & Fischer M. (2000). Feasibility Study of 4D CAD in Commercial Construction. Journa of Construction Engineering and Management, ASCE, Vol. 126, No. 4, 251-260.

Staub., S. & Fischer M. (2001). Industrial Case Study of Electronic Design, Cost, and Schedule Integration, Center for Integrated Facilities Engineering, Stanford University,

Tatum C. & Korman T. (2000). Coordinating building systems: process and knowledge, Journal of Architectural Engineering, Vol. 6, No. 4, 116-121.

Whyte, J., Bouchlaghem, N. & Thorpe, A. (2000). From CAD to virtual reality: modeling approaches, data exchange and interactive 3D building design tools. Automation in Construction, Vol. 10,

Time is precious

don’t waste it!

Plagiarism-free

guarantee

Privacy

guarantee

Secure

checkout

Money back

guarantee