The Embodied Energy of Wind Farm Construction, Thesis Paper Example

Background

Although the primary aim of constructing a wind farm is to stop global warming that stems from the emission of toxic gases, gaining profit is party significant. The Embodied is the energy consumed during production, including installation, manufacturing, maintenance, and construction stages (Mendecka and Lombardi, 2019). There is an increasing trend in Australia associated with large scale wind turbines’ investment, most of which is based on the justification of the Embodied energy. According to numerous studies, the embodied energy in many cases is 5% or less of the generated energy throughout the service life of the wind turbine (Mendecka and Lombardi, 2019). The variability of the Embodied energies of different wind turbines apart from the technical makeup is the assessment method, location, turbine size, energy intensities, and materials used, among others.

The errors that stem from the calculation of Embodied energy stem from using process-based energy, which uses a specific number of inputs; therefore failing to account for smaller inputs (Carriveau, & Ting, 2018). Ultimately, the calculation only accounts for approximately 80% of the total Embodied energy. Apart from the conventional additions, other factors that must be considered include wiring, access roads, grid connections, and transformers.

Introduction

The embodied energy is a term that is very common in building. There are two categories of embodied energy; initial and recurring. Initial embodied energy refers to the consumed energy in assembling, manufacture and transport of construction materials. Recurring embodied energy on the other hand is that which is expended during maintenance or repair of construction materials. According to a CMC study conducted on a 40 year old building the total breakdown energy is approximately 15% – 16% embodied energy and 9% – 10% recurring embodied energy. The embodied energies of materials vary between different materials; for instance, concrete has a high value in comparison to wood. Contrary to popular beliefs, embodied energy bases on material usage rather than form of use. In many cases, the wind farm life is expected to be more than 20 years.

Embodied Energy for different materials

| Materials | Energy MJ/kg |

| Copper | 100 |

| Plastics | 90 |

| Cement | 5.6 |

| Concrete Blocks | 1.5 |

| Aluminum | 170 |

| Glass | 12.7 |

| Clay Bricks | 2.5 |

The actual embodied energy of materials value according to the location for the same material.

Recycled or reused aluminum among other construction materials have 10% less embodied energy in comparison to newly manufactured aluminum.

The Goal of the study

The objective of the analysis, in this case, is the evaluation of the expected environmental impact of the operation of electricity production on a wind farm. The analysis will include factors such as the used raw materials, fabrication of the site parts, construction, and turbine operations, among others. The wind farms chosen for the study are those that characterize a typical Australian wind farm. The site parameters chosen for the analysis will be similar to the conventional size of a wind farm containing V112 turbines (Carriveau, & Ting, 2018). The scope of the examination will encompass the manufacturing process, logistics, replacement parts, transportation of wind plant components, raw materials’ construction usage, among others. In some cases of the analysis, the maintenance and production of the wind farm’s infrastructure have been excluded as part of the study.

Typical Australian Wind Farm

In this case, the criteria used to define a typical Australian wind farm include topography type, number of turbines, quantities of WTG footing quantities (steel and concrete), turbine origins, total multi-use facilities, and earthworks on site, among other factors. There are numerous Australian wind farms, including Moorabool North Wind, Moorabool South Wind, Murra Warra Wind Farm, Cattle Hill Wind, Lal Wind, Sapphire Wind, and Cherry Tree Wind Farms. The approximate size of an Australian wind farm turbine that is onshore is 2.5-3 MW with 50m blades; the power, in this case, can serve up to 1500 households.

Embodied Energy for a Typical Australian Wind Farm

Most of the turbines in Australia have turbines that run from 1.5-3MW; depending on the wind farm’s size, the number of turbines may be as many as 48. In this case, we will assume the rated turbine output to be 3MW, with 33% capacity factor, 80m hub height, 4m/s cut-in wind speed, 44/90 ratio of blade length to rotor diameter, and 25m/s cut-out wind speed. The turbines have three blade systems and a horizontal axis with a 20-year lifer service.

Cherry Tree Wind Farm

The Wind Farm is found in Victoria, near Seymour is 40 hectares. The wind turbine technology used by the farm is the Vestas V136. The power output capacity is approximately 57.6 MW, capable of powering over 30,000 homes from 16 turbines; each turbine has a power output capacity of 3.6 MW. The most significant advantage of the farm is the reduction of carbon dioxide in the air, similar to the amount produced by 60,000 cars. The life wind farm is estimated to be 30 years. The topography type is medium.

Standard Applied

Vestas V112 (Turbine Model)

Tower height – 84 meters

Rotor Diameter – 112 meters

Cherry Wind Farm Assessment

| Description | Unit | Quantity |

| Life Cycle | Years | 30 |

| Plant Size | MW | 57.6 |

| Wind Class | – | High IEC1A |

| Foundation Type | – | The medium ground water level |

| Grid Distance | km | 187 |

| Plant Location | – | Australia |

| Rotor Diameter | m | 112 |

| Generator Type | – | Induction |

| Rating per turbine | MW | 3.6 |

| Tower Type | – | Steel |

| Production at 7.5 m/s | MWh per year | – |

| Production at 8.5 m/s | MWh per year | – |

| Production at 10 m/s | MWh per year | 15,600 |

| Hub Height | m | 100 |

| The turbine in the Wind Farm | – | 16 |

Note: The above assessment for the Cherry wind farm comprises of all losses (with a 96% availability), 6% average wind farm losses, and up to 2.5% losses up to the grid.

Materials for the Wind Farm

- 1176t Reinforced Steel for the Foundation (36t Steel)

- 160t Painted steel for the tower

- 13t Bedplate

- 7.14t Generator

- 24.06t Gear Box

- 19.2t Hub

- 3.87t Revolving System

- 1.02t Brake System

- 6.93t transformers (and sensors)

- 1.02t Crane

- 20.07t Blades

Assumptions

- The distribution of wind velocity must remain based on Weibull’s concept of distribution. (Carriveau & Ting, 2018)

- Maintenance, including lubrications, take place every five years.

- Component replacement (half of the gearbox)

- The use of recycled materials has not been included in the examination.

- There is a regular replacement of some parts, such as blades and generators (Carriveau, & Ting, 2018).

- Energy Output = Gross Energy Output – Initial Embodied Energy

Results

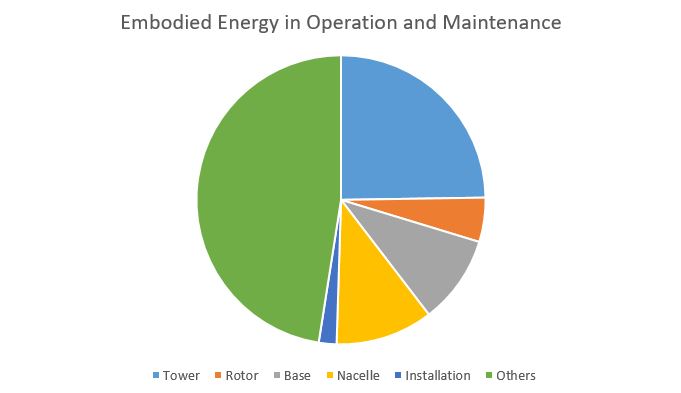

Embodied Energy (Operation and Maintenance)

| Component | Percentage | Energy |

| Tower | 25% | 21,059.25 GJ |

| Rotor | 5% | 4,211.85 GJ |

| Base | 10% | 8,423.7 GJ |

| Nacelle | 10% | 9,266.07 GJ |

| Installation | 2% | 1,684.74 GJ |

| Cables

Generator Brake System Crane Gear Box Cover Main Shaft Yaw System Hydraulic System Others |

51% | 42,960.87 GJ |

| Total | 84, 237 GJ |

A considerable percentage of the embodied energy was from the “others” category. Most of the same category components are applied for maintenance purposes, such as gear replacements and lubrication of the hydraulic system. The nacelle, base, rotor, and tower are embodied energy spent during operation (Carriveau, & Ting, 2018). The least percentage of embodied energy, in this case, is from the installation category (2%).

Embodied Energy in Transport

Owing to the large distance from the dock (approximately187km), the energy consumption in transport will account for about a considerable percentage of the total embodiment energy. The total embodied energy is 200,000 GJ.

Embodied Energy for Land Reclamation and Decommissioning

Land Reclamation – 1500 GJ (Assumed Value)

Wind Farm Decommissioning – 4200 GJ (Assumed Value)

Total: 5700 GJ

Construction Materials

| VDA MATERIAL CLASSIFICATION | AMOUNT, TONNES |

| Nonferrous heavy meatal, cast and wrought alloys | |

| Copper alloys | 0.1 |

| Zinc alloys | 0.01 |

| Copper | 157 |

| Light alloys cast and wrought alloys | |

| Aluminum and aluminum alloys | 109 |

| Special metals | |

| Special metals | 2700g |

| Steel and iron materials | |

| High alloyed | 1420 |

| Cast iron | 2150 |

| Steel and iron materials( unspecified) | 6 |

| Unalloyed, low alloyed | 6500 |

| Others | |

| Chromium | 0.30 |

| Concrete | 28000 |

| Manganese | 15 |

| molybdenum | 0.15 |

| Plastic | 13 |

| silicon | 3.5 |

| vanadium | 0.49 |

| Steel | 223 |

| Stainless steel | 13 |

| Glass fiber | 22 |

Embodied Energy of Construction Materials

| VDA MATERIAL CLASSIFICATION | AMOUNT, TONNES | ENERGY INTENSITY(GJ/TONNE) | EMBODIED ENERGY (GJ) |

| Nonferrous heavy metal, cast and wrought alloys | – | – | |

| Copper alloys | 0.1 | – | – |

| Zinc alloys | 0.01 | 51 | 0.51 |

| Copper | 157 | 97.6 | 15323.2 |

| Light alloys, cast and wrought alloys | |||

| Aluminum and aluminum alloys | 109 | 201.057 | 21915.213 |

| Special metals | |||

| Special metals | 2700g | – | – |

| Steel and iron materials | |||

| High alloyed | 1420 | – | – |

| Cast iron | 2150 | 23.5 | 50525 |

| Steel and iron materials | 6 | 25.04 | 150.24 |

| Unalloyed, low alloyed | 6500 | – | – |

| Others | |||

| Chromium | 0.30 | 82.9 | 24.87 |

| Concrete | 28000 | 1.003 | 28084 |

| Manganese | 15 | 51.5 | 772.5 |

| molybdenum | 0.15 | 378 | 56.7 |

| plastic | 13 | 60.9 | 791.7 |

| silicon | 3.5 | 158.6 | 555.1 |

| vanadium | 0.49 | 3711.2 | 1818.488 |

| Steel | 223 | 32.614 | 7272.922 |

| Stainless steel | 13 | 74.8 | 972.4 |

| Glass fiber | 22 | 29.265 | 643.83 |

| TOTAL | 41736.55 | 4978.979 | 128906.673 |

Embodied Energy of Production

Manufacture and Dismantling – 54,443.375 GJ

Total number of turbines – 16

Total Energy of Production = 1,000,000 GJ

Embodied Energy of Construction and Site Preparation

| Description | Embodied Energy |

| Construction Materials (Foundation) | 35,000 GJ |

| Site Office | 75 GJ |

| Equipment and Fixed Assets | 1200 GJ |

| Cables | 20,000 |

| Road and Path development | 50000 GJ |

| Total | 106,275 GJ |

Discussion

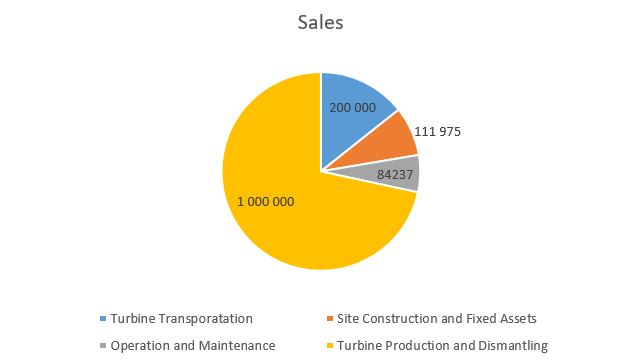

The total embodied energy in the wind farm is 1,396,212 GJ. The Cherry farm’s wind farm cycle is divided into turbine production, construction, transport, operation, and maintenance. The energy directly from the wind accounts for the total spent on operation and maintenance. The largest percentage of the embodied energy stems from the production of energy in the Cherry Wind Farm. The production category, in this case, accounts for the largest percentage of embodied energy. The dismantling and production encompass the construction materials (Carriveau, & Ting, 2018). The transportation embodied energy is arguably small due to the fact that the dock is nearer than in most cases (187km). In some cases, the distance travelled may be as far as 600km or more from the construction site of the wind farm (Carriveau, & Ting, 2018).

Phase Percentage of Embodied Energy

Turbine Transportation 14.32%

Site Construction and Fixed Assets 8.04%

Operation and Maintenance 6.05%

Turbine Production and Dismantling 71.83%

As discussed above, the cycle with the highest number of processes is the manufacturing cycle, followed by the extraction of raw materials. An in-depth analysis of the specific life cycles of these two processes indicates that their energy consumption is significantly high. Machining, a process in manufacturing, tops the list of the most energy-demanding processes. Most elements in the wind farm are produced through forging, casting, and rolling. These are traditional metal operation approaches that consume significant energy. For the manufacturing process to be completed, the energy demand is relative to the material waste that will be produced (Moradnazhad & Unver, 2016). Manufacturing firms are required to produce products with the highest flexibility in the shortest time possible. In most manufacturing plants, manufacturing at the shortest time possible requires the use of machine tools, which significantly utilize electrical energy. Machining thus accounts for over ninety percent of the carbon footprints recorded in the manufacturing process. Guerra-Zubiaga Al Mamun & Gonzalez-Badillo (2018) allude that during machining, the demand for electrical energy is associated with machine tool start-to-stop. A larger percentage of energy is consumed during this process as compared to the actual material removing process. Energy consumption in the manufacturing stage is thus very challenging to regulate unless there is a complete change of machine tool design. Machining involves many processes, including milling, and for the process to be complete further modifications, including painting, must be made to promote aesthetics. Other elements, including plastics that require glass reinforcement, also demand the use of machine tools for efficiency in terms of productivity. The machine tools highly consume electrical power.

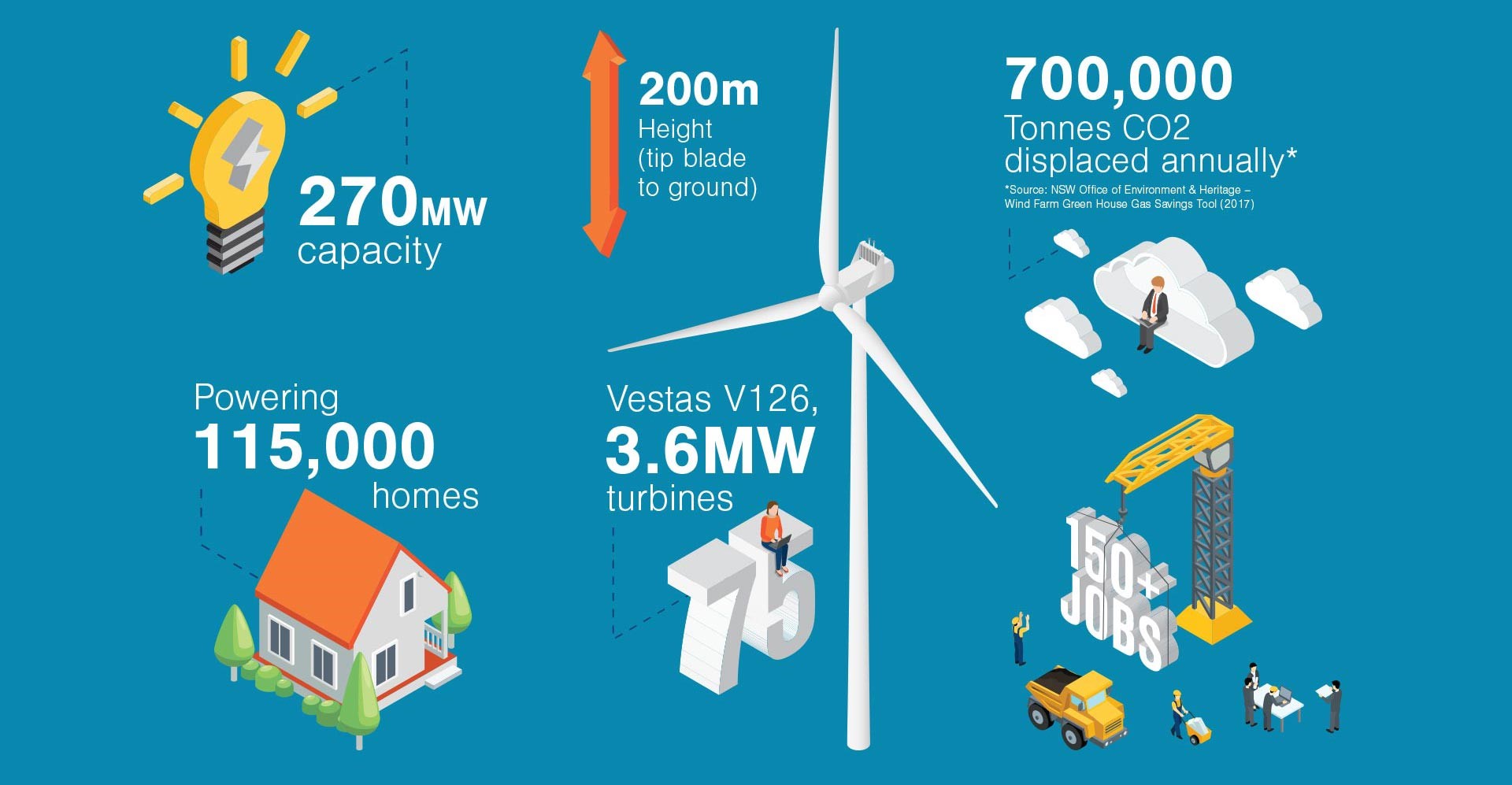

Sapphire Wind Farm

Background

The Sapphire Wind Farm, built in 2017, is located in South Wales. At the time, the farm was the largest in New South Wales. The construction of the wind farm begin during the beginning of 2017 and became commissioned in at the end of the same year. Sapphire is located Gwydir Highway’s north, Inverell’s east and west of Glenn Innes. The farm powers more than 115,000 homes with more than 270MW (“Sapphire Wind Farm”). The farm has 75 turbines, and the tip blade ground height is 200 m to the ground (“Sapphire Wind Farm”). The most significant advantage of the wind farm is that it displaces approximately 700,000 tonnes of carbon dioxide. Unlike the Cherry Farm, which uses V112, the Sapphire Wind Farm utilizes the V126 turbines (“Sapphire Wind Farm”). The life of the wind farm is approximately 25 years. The farm’s topography type is medium; the origin of both the turbines and towers is VESTAS. The wind farm is approximately 430km from the dock (“Sapphire Wind Farm”). The strip depth of the project was 100m.

Standard Applied

Vestas V126 (Turbine Model)

- Hub height – 3.8 meters

- Rotor Diameter – 126 meters

- Materials for the Sapphire Wind Farm

- 2475 t Reinforced Steel for the Foundation (495t Steel)

- 350 t Painted steel for the tower (0.93t paint)

- 16.75 t Bedplate

- 15.95t Generator

- 31t Gear Box

- 24t Hub

- 5t Revolving System

- 1.3t Brake System

- 8.95t transformers (and sensors)

- 1.3t Crane

- 25.1t Blades

- Assumptions

The distribution of wind velocity must remain based on Weibull’s concept of distribution. (Carriveau & Ting, 2018)

Maintenance, including lubrications, take place every three years.

The land commissioning embodied energy is reasonably assumed.

There is a regular replacement of some parts, such as blades and generators (Carriveau, & Ting, 2018).

Cherry Wind Farm Assessment

| Description | Unit | Quantity |

| Life Cycle | Years | 25 |

| Plant Size | MW | 270 |

| Wind Class | – | High IEC1A |

| Foundation Type | – | The medium ground water level |

| Grid Distance | km | 430 |

| Plant Location | – | Australia |

| Rotor Diameter | m | 126 |

| Generator Type | – | Induction |

| Rating per turbine | MW | 3.6 |

| Tower Type | – | Steel |

| Production at 7.5 m/s | MWh per year | – |

| Production at 8.5 m/s | MWh per year | – |

| Production at 10 m/s | MWh per year | 15,600 |

| Hub Height | m | 87 |

| The turbine in the Wind Farm | – | 75 |

Results

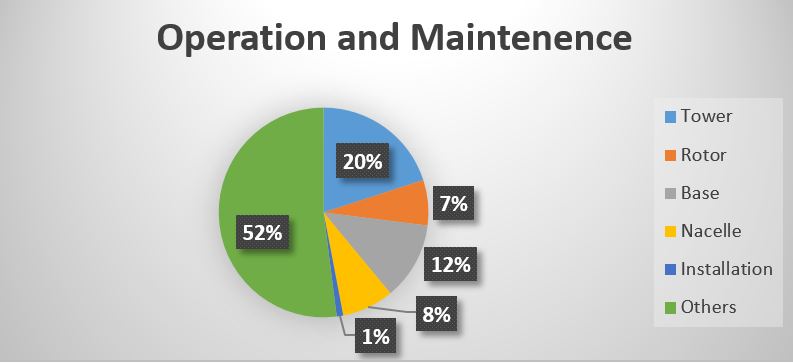

Embodied Energy (Operation and Maintenance)

| Component | Percentage | Energy |

| Tower | 20% | 50,564.4 GJ |

| Rotor | 7% | 17,697 GJ |

| Base | 12% | 30,338 GJ |

| Nacelle | 8% | 202,257 GJ |

| Installation | 1% | 2,528.22GJ |

| Cables

Generator Brake System Crane Gear Box Cover Main Shaft Yaw System Hydraulic System Others |

52% | 131,467 GJ |

| Total | 252,822 GJ |

Embodied Energy for Operation and Maintenance

Although the “others” account for the largest percentage of operation and maintenance, it is safe to assume that the individual component percentage each element could be less. Therefore, the tower (20%) followed by the base (12%) have the highest embodied energy. The installation category account for the least percentage of the total embodied energy. The total embodied energy of the operation and maintenance in this case is considerably significant in comparison to the Cherry Farm (almost three times more) owing to the large power output. The farm size is large and therefore the operation and maintenance (and their corresponding weight) would be more (“Sapphire Wind Farm”). However, the percentages are almost similar in relation to the embodied energy of the operation and maintenance.

Construction Materials

| VDA MATERIAL CLASSIFICATION | AMOUNT, TONNES |

| Nonferrous heavy metal, cast and wrought alloys | |

| Copper alloys | 0.3 |

| Zinc alloys | 0..3 |

| Copper | 465 |

| Light alloys cast and wrought alloys | |

| Aluminum and aluminum alloys | 318 |

| Special metals | |

| Special metals | 7500g |

| Steel and iron materials | |

| High alloyed | 3960 |

| Cast iron | 6390 |

| Steel and iron materials( unspecified) | 12 |

| Unalloyed, low alloyed | 18900 |

| Others | |

| Chromium | 0.60 |

| Concrete | 78000 |

| Manganese | 39 |

| molypdenum | 0.39 |

| Plastic | 30 |

| silicon | 9.9 |

| vanadium | 1.17 |

| Steel | 660 |

| Stainless steel | 36 |

| Glass fiber | 60 |

Embodied Energy of Construction Materials

| VDA MATERIALCLASSIFICATION | AMOUNT, TONNES | ENERGY INTENSITY(GJ/TONNE) | EMBOIDED ENERGY (GJ) |

| Nonferrous heavy metal, cast and wrought alloys | – | – | |

| Copper alloys | 0.3 | – | – |

| Zinc alloys | 0.3 | 51 | 15.3 |

| Copper | 465 | 97.6 | 45384 |

| Light alloys , cast and wrought alloys | |||

| Alluminium and allumium alloys | 318 | 201.057 | 63936.126 |

| Special metals | |||

| Special metals | 7500g | – | – |

| Steel and iron materials | |||

| High alloyed | 3960 | – | – |

| Cast iron | 6390 | 23.5 | 150165 |

| Steel and iron materials | 12 | 25.04 | 300.48 |

| Unalloyed, low alloyed | 18900 | – | – |

| Others | |||

| Chromium | 0.60 | 82.9 | 49.74 |

| Concrete | 78000 | 1.003 | 78234 |

| Manganese | 39 | 51.5 | 2008.5 |

| molybdenum | 0.39 | 378 | 147.42 |

| plastic | 30 | 60.9 | 1827 |

| silicon | 9.9 | 158.6 | 1570.14 |

| vanadium | 1.17 | 3711.2 | 4342.104 |

| Steel | 660 | 32.614 | 21525.24 |

| Stainless steel | 36 | 74.8 | 2692.8 |

| Glass fiber | 60 | 29.265 | 1755.9 |

| TOTAL | 116382.66 | 4978.979 | 373,953.75 |

The embodied energy has increased significantly in comparison to the Cherry Wind Farm’s case. The Sapphire farm is considerably large as expected due to the large power output and number of turbines (75). The wind farm uses large quantities of materials; the number and weight of materials is directly proportional to the embodied energy of the material. Therefore, the more the materials the more the embodied energy depending on the energy intensity of the material.

Embodied Energy of Production

Manufacture and Dismantling – 100,455.875 GJ

Total number of turbines – 75

Total Energy of Production = 4,534,190.625 GJ

Embodied Energy in Transport

The distance from the dock is very large in comparison to the Cherry Wind Farm (approximately 187km). In this case, the distance is 430km. Since the distance is significant the energy consumption in transport will account for about a considerable percentage of the total embodiment energy (more than the embodied energy of transport in the Cherry Wind Farm). The total embodied energy is 745,000 GJ.

Embodied Energy for Land Reclamation and Decommissioning

Land Reclamation – 7000 GJ (Assumed Value)

Wind Farm Decommissioning – 13,000 GJ (Assumed Value)

Total = 20,000 GJ

Embodied Energy of Construction and Site Preparation

| Description | Embodied Energy |

| Construction Materials (Foundation) | 105,000 GJ |

| Site Office | 375 GJ |

| Equipment and Fixed Assets | 4800 GJ |

| Cables | 80,000 |

| Road and Path development | 225,000 GJ |

| Total | 415,175 GJ |

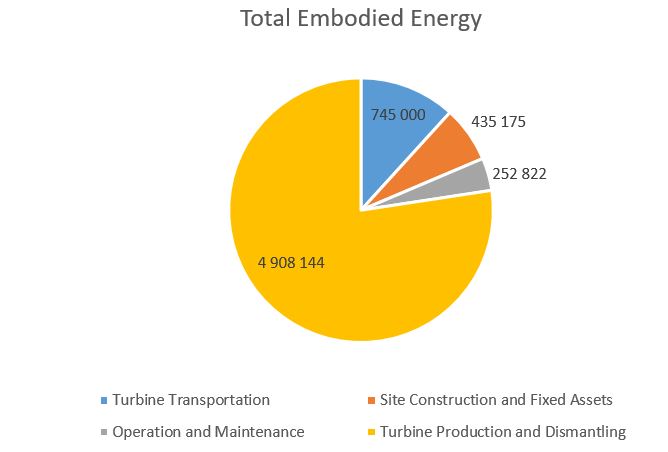

Total Embodied Energy

Discussion

Total Embodied Energy: 6,341,141 GJ

Phase Percentage of Embodied Energy

Turbine Transportation 11.749%

Site Construction and Fixed Assets 6.862%

Operation and Maintenance 3.987%

Turbine Production and Dismantling 77.40%

Cherry Wind Farm (Comparison)

Phase Percentage of Embodied Energy

Turbine Transportation 14.32%

Site Construction and Fixed Assets 8.04%

Operation and Maintenance 6.05%

Turbine Production and Dismantling 71.83%

As in the case of the Cherry Wind Farm, the turbine production and dismantling account for the largest percentage of the embodied; the statistics stems from the fact that that the category includes the reconstruction (which translates to additional embodied energy from the construction materials. Operation and maintenance process uses the least embodied energy (3.987%). The turbine transportation embodied energy is considerably high in this case in comparison to the Cherry farm due to the increased number and weight of the materials transported in addition to the distance from the dock. The total embodied energy is much more than the case of the Cherry farm. Fundamentally, the Sapphire Wind is large both in expected power output and physical size. The operations or processes of the wind life cycle may be similar but the work done is much more in the case of the Sapphire Wind Farm (“Sapphire Wind Farm”). The hierarchy of processes in terms of the embodied energy from the highest to lowest is the Turbine Production and Dismantling, Turbine Transportation, Site Construction and Fixed Assets and the Operation and Maintenance processes. According to the analysis of the two farms, there is a relationship between the farm size and the embodied energy of the processes.

Analysis of Energy Consuming Processes

As aforementioned, the wind farm life cycle includes the extraction of raw materials, manufacturing of various components, transportation to the site, installation, operation period, and end of life. The impact on the environment varies for each cycle, depending on the amount of energy used in specific processes. The amount of energy utilized in each process in the farm’s life cycle is also dependent on the size and location of the wind farm(“Sapphire Wind Farm”). Since each wind farm life cycle has a specific amount of processes, the energy demands vary depending on the requirements of each process. In many cases, machining a process in manufacturing, tops the list of the most energy-demanding processes especially in a wind farm. The supply chain in the wind arm life cycle is complex and has to be modeled for specific processes and products downstream to the end of the life cycle. The proceeding analysis will itemize data to support the postulate that more energy is utilized during the primary material production of the wind turbine parts.

Other Common Australian Wind Farms

The Australian Wind Farms vary in size which according to the aforementioned discussion ultimately affects their embodied energy. The Lal Lal Wind Farm is found in Australia with a life of 30 years and a total output of 216MW. Cattle Hill Wind farm producing approximately 144MW has 48 turbines and a farm life of 20 years at minimum. Finally, Murra Warra Wind Farm, found in Australia has a power output of 225.7 MW and a farm life of 25 years. Even though, there is no literature that contains the analysis of the embodied energies of each of the wind farms, it is possible to tell the value based on the farm size, power output, number of turbines, magnitude of processes and construction materials used among others.

Trends in Energy Requirements

From the analysis of the embodied energy in various wind power stations, it is reasonable to assume that there are specific trends in the wind farm life cycle that facilitate increasing energy demands. The energy demands for each process tend to vary significantly depending on the life cycle stage considered (Ardente et al., 2008). There is a behavior becoming increasingly common where various farms are shifting to the use of large-scale wind turbines. Land scale turbines promote increased efficiencies of scale and significant energy output per particular turbine.

The increasing trend towards more giant turbines, however, comes with increased demands for specifications in the mining and processing of required raw materials. This is since there has been little or no change in the type of material other than the increased intensity of the material extraction and use. There has been little consideration of the additional energy requirements of this increase. Demands for new raw materials and manufacturing is dependent on the length of time required or the operability of specific wind farm elements. With the increased technological improvements, the elements used in the wind farm have been reinforced, and others modified to permit stress-free recycling (Ardente et al., 2008). Recycling reduces the energy demands for the extraction of raw materials but increases the demands for manufacturing processes. This contributes to the variance in making energy demands for primary material production more significant compared to other processes in the life cycle.

Recommendations on reducing the embodied energy

- Using concrete mixes with low-carbon (concrete is the largest component of embodied energy in any construction).

- Reducing usage of carbon-intensive components. Some of the products in this case include aluminium, foam insulation and a wide array of plastics.

- Usage of recycling or reusing as opposed to newly manufactured materials considering the fact that they have lower embodied carbon.

- Waste minimization.

- Structural Efficiency Maximization.

- Usage of carbon sequestering components.

Life Cycle Analysis

Extraction of Raw Materials

Processes in this stage include mining and processing of raw materials for materials such as copper, glass, glass-reinforced plastic, and steel. Processing involves harvesting and refining the materials from the rock and ore using complex processes, including separation and chemical-reduction procedures. From the analysis of the embodied energy, it is evident that energy input varies depending on the type of material. Metallic materials such as steel and plastic material requiring reinforcement using glass, for instance, require more energy as compared to concrete. This variation arises majorly due to differences in extraction requirements. The majority of the metallic materials needed are acquired from metal ores, either oxides or compounds with sulfur. The reduction process of these oxides or compounds is highly energy demanding. The energy demands are primarily relative to the nature of the energy source (Chipindula et al., 2018). Through the embodied analysis, inventory analysis of the onshore and offshore wind farms was done based on technical data obtained from specific power plants. Onshore foundations, in this case, include the farms that are designed mostly using concrete and have a small amount of steel reinforcement. Offshore structures are required to have maximum resistances as they are situated in adverse environmental conditions. For offshore stations, therefore, the materials, including steel, require amplified reinforcements that consequently result in more energy demands. The wind farm has varied elements, each requiring specified production processes.

Manufacturing Process

Various components require specified manufacturing processes, but the primary ones used for materials required in a wind farm are forging, composite forming, casting, construction, and rolling. Machining is a dominant energy-demanding procedure of manufacturing. The global energy demand for metal production through manufacturing parts accounts for over seven percent of total global energy. The increased demand for larger turbines makes manufacturing more energy demanding. From the various analyses, manufacturing processes can be performed using recycled and non-recycled materials (Guerra-Zubiaga Al Mamun & Gonzalez-Badillo, 2018). A lot of energy is consumed during the primary manufacture of the turbine parts using primary materials. After the end of the wind farm cycle, the manufacturing process for the new plant will utilize the required material and will consequently demand additional costs. At the end of the life cycle, almost 1.1% of the total energy requirement will be used to process the recycled material. Material recycling enables manufacturing firms to recapture some of the energy from material waste. In the recycling process, about eighty percent of the energy spent in the processing cycle can be recovered (Guerra-Zubiaga Al Mamun & Gonzalez-Badillo, 2018). The recycling process thus results in the recovery of over fifty percent of energy depending on the size of the farm. During the manufacturing process, the aesthetic value of the material used is usually put into consideration. The energy consumption in the finish machining is thus relative to the amount of waste material resulting from the manufacturing process.

Transportation to Site

From the analysis of the embodied energy, the difference in the energy requirements for transportation is primarily determined by the location and type of wind farm, whether onshore or offshore. Despite this variance in the energy demands, the requirements for the transportation cycle do not match other processes in the entire wind farm life cycle. The energy requirements and environmental concerns in this cycle are primarily associated with the energy utilized in the movement of turbine parts. Since wind farms are situated in open locations with minimum human development, they are usually far from places of manufacturing of the elements. Wind farms are also preferably located in hilly areas that require energy-intensive transport processes to access. In offshore wind farms, towers and foundations are usually processed near the farm locations to mitigate the difficulties associated with the transportation of heavy parts. According to Chipindula et al. (2018), truck transportation is usually the primary form of transportation of turbine parts for farms situated in onshore locations. Offshore wind farms require the use of trucks and, after that, the use of boats or ships. The transportation energy demands for offshore farms are thus more significant than for the onshore. Fixed turbine parts also use high energy as they require the use of large trucks or ships. From the embodied energy analysis, major fixed turbine parts for offshore farms include tower and foundation.

Considering a life cycle assessment of transportation, energy is primarily required or fuel. Significant forms of transportation in the analyzed wind farms use fuel-powered locomotives for transport purposes. The life cycle effects associated with the use of fuel energy for transportation primarily include upstream impacts such as extraction and manufacturing of fuel products and infrastructure required to supply fuel energy. In the wind arm perspective, however, what significantly contributes to the energy requirement is the use of energy in vehicles and the associated effects, including emissions from the vehicles. Considering the considerable percentage of the fixed turbine parts and the significant location of farms from the manufacturing firms, a considerable sum of energy consumption is registered in the transportation process (Chipindula et al., 2018). Transportation to the site, despite being an energy-consuming process, does not, however, contain many energy-intensive procedures as compared to the extraction of raw materials and manufacturing of elements cycles. The energy demands only vary depending on the location of the wind farm and the specific types and number of transportation mechanisms required. The transportation procedure only has one life cycle process that is relative to the wind farm energy requirements.

Installation Cycle

Despite various wind farms using different approaches of installation, all of the farms require conventional construction equipment. The location of wind farms determines the type of conventional equipment required and the energy consumption required for the entire process. Onshore installation primarily requires the use of construction equipment, including forklifts, cranes, and excavators. Cranes, excavators, and forklifts are usually designed to utilize large amounts of fuel to enhance their workability. Apart from the energy required for lifting the elements and putting them together, more energy is utilized in moving the machines around (Moradnazhad & Unver, 2016). Offshore farm installation, on the other hand, demands more energy for additional equipment, including boats and hydraulic hammers. The offshore farm installation also varies depending on the depth of the water of the installation location. Shallow-water turbines demand more energy for monopile foundation and transition pieces. Chipindula et al. (2018) allude that turbine installation on shallow waters requires more specifications, including jack-up platforms and pieces for transition, which demand additional energy during transportation and installation. The offshore installation also requires the use of a large amount of concrete, and this increases the energy requirements. Deep-water installation is supposed to be the most energy-intensive process in the installation cycle. The energy consumption is, however, lower due to the required complete onshore assembly of the elements before they are transported to the site (Chipindula et al., 2018). Deep-water installation is founded on tri-floater conformation, which is less energy-demanding as it only uses a completely assembled turbine. Fuel consumption for the offshore deep-water installation is thus lower as compared to offshore in-water installation.

Operation Period and End of Life

From the embodied energy analysis, the operation cycle is the least energy-consuming phase utilizing less than three percent of the total energy input. The value of this energy use includes demands for maintenance and inspection. Maintenance always results in oil changes, the addition of lubricants and additional fuel for transportation. From the previous analysis, most operation centers are usually located far from the firms and are done virtually (Ghenai, 2012). There are, therefore, few instances where personnel access the wind farm and also a small number of maintenance activities. Since the frequency of replacement of material elements used in the wind farm is low, its energy consumption is negligible when compared to the energy requirements for other cycles, including manufacturing (Ghenai, 2012). There are usually little or zero chances of replacement of the primary turbine elements for a minimum period of twenty years. A meta-analysis of various research papers indicates that the replacement period for the gearbox, which is primarily made of cast iron and steel, ranges between 5-10 years. The end of the life cycle, on the other hand, primarily result in the addition of energy requirements to the manufacturing sector.

Conclusion

Most professionals in manufacturing and construction farms fail to appreciate the significance of embodied energy. The problem of pollution is increasing significantly daily and instead of focusing on the fundamental sources, most individuals work backwards. It is best to take preventive measures rather than dealing with solutions after occurrences. Some people perceive the embodied energy of materials and processes as being minimal which is untrue. Additionally, focus on the aspect will save energy in the wind farm life cycle processes especially in manufacturing. Embodied energies largely depend on the location among other factors. Therefore apart from looking into the carbon content of construction materials, it is equally important to the materials that work best under particular conditions. As aforementioned, the recycling and reuse of construction materials reduces the energy embodied as opposed to use of new materials.

Bibliography

Ardente, F., Beccali, M., Cellura, M., & Lo Brano, V. (2008). Energy performances and life cycle assessment of an Italian wind farm. Renewable and Sustainable Energy Reviews, 12(1), 200-217. https://doi.org/10.1016/j.rser.2006.05.013

Carriveau, R., & Ting, D. S.-K., 2018. Wind and solar-based energy systems for communities. The Institution of Engineering and Technology.

Chipindula, J., Botlaguduru, V., Du, H., Kommalapati, R., & Huque, Z. (2018). Life Cycle Environmental Impact of Onshore and Offshore Wind Farms in Texas. Sustainability, 10(6), 2022. https://doi.org/10.3390/su10062022

Ghenai, C. (2012). Life Cycle Analysis of Wind Turbine. Sustainable Development – Energy, Engineering, and Technologies – Manufacturing, And Environment. https://doi.org/10.5772/29184

Guerra-Zubiaga, D., Mamun, A., & Gonzalez-Badillo, G. (2018). An energy consumption approach in a manufacturing process using the design of experiments. International Journal of Computer Integrated Manufacturing, 31(11), 1067-1077. https://doi.org/10.1080/0951192x.2018.1493234

Moradnazhad, M., & Unver, H. (2016). Energy consumption characteristics of turn-mill machining. The International Journal of Advanced Manufacturing Technology, 91(5-8), 1991-2016. https://doi.org/10.1007/s00170-016-9868-6

Mendecka, B., and Lombardi, L., 2019. Life cycle environmental impacts of wind energy technologies: A review of simplified models and harmonization of the results. Renewable and Sustainable Energy Reviews, 111, pp.462-480. https://doi.org/10.1016/j.rser.2019.05.019

Sapphire Wind Farm. Inverell Shire Council., 2020, March 19. https://inverell.nsw.gov.au/building-and-development/wind-farms/sapphire-wind-farm/.

Time is precious

don’t waste it!

Plagiarism-free

guarantee

Privacy

guarantee

Secure

checkout

Money back

guarantee