The ERP Program Implementation, Essay Example

Abstract

The ERP program implementation requires multiple changes to the business processes as well as the implementation of new software technology. To establish a complete project there must first be a plan. The project plan incorporates multiple areas including scope, pricing, cost control, quality management and risk mitigation to name a few. The project plan provides the basis for understanding for what the project is and is intended to provide at the conclusion of the project lifecycle. It also provides a frame of reference during the project lifecycle for stakeholders to view and gain perspective on what the pure intentions of the project are. This plan will outline the necessary information regarding the ERP implementation for a manufacturing firm.

Project Scope

The project’s scope is defined by the Project Management Book of Knowledge 2008 (PMBOK) as “The work that needs to be accomplished to deliver a product, service or result with the specified features and functions”. So in order to have a project plan it is first necessary to understand what project is being undertaken and what it will take the provide the desired results necessary to accomplish those project objectives. The process of defining the scope of the project would, in reality, require the input of the subject matter experts to conduct a workout session to determine initially how the large project could be divided and implemented based upon how the legacy operations are operated and their unique dependencies and requirements. In the current project development there was a distinguised need to integrate and build a complete wing-to-wing information system that would become a fully integrated tool for the business to utilize throughout the entire product lifecycle. The business leaders determined that there was a need for a better and more efficient way of conducting current processes.

A solution in the form of collaborative effort by the business and information technology teams found that an Enterprise Resource Planning program could provide what the company needed. In this project it is vital to understand that while the replacement of legacy information technology systems will occur there are changes to the business processes that will drive the technology used for implementation. The information technology proceses and systems will change but how the business is conducted from procurement of goods from a supplier, through manufacturing and production to ultimately providing a finished product will change as well.

In order to understand the scope and how the project will be implemented there needs to be a base of what is going to be a large scale implementation project (Prencipe, Davies, & Hobday 2007). ERP is an approach to remove uncessary and wasteful business processes as well as sunsetting applications that are aging and become an hinderence on the business. The ERP system provides a continual package of applications and business processes built and purposed to complimentary and integrated.

The span of this projcect encompasses multiple operating functions including accounting/finance, sourcing, manufacturing, scheduling, information technology and quality. Implementation of a project involving the ERP foundation involves IT system adaptations, removals and replacements as well as those necessary business process changes.

The benefits of ERP include real-time data transfer from one source of data. This is due to the fact that the sourcing systems used to procure parts for the manufacturing teams are colocated in the same environment and survive in an environment where updates and changes are felt throughout the process. The ERP program works by eliminating legacy and antiquated systems that are disparate from the collaborative efforts the ERP program strives for.

The larger the project, the more imperative it is to clearly define the scope of the project (Kanaracus 2012). The scope of this project entails changing an entire manufacturing plant over from one group of disparate systems to a new technology and business process. The scope of this project is to take the core sourcing and manufacturing activities out of the legacy systems and move them to a new business and technological solution. After industry research and consultation on ERP implementations, both successes and failures, it was critical to provide a basis or foundation of the ERP program and expand on the foundation with quality centric projects based in lean methodology and six sigma framework. Considering the potential size and complexity of implementing a project that is purported to reduce complexity, improve efficiency, remove communication barriers and provide real-time or near real-time user feedback it is important to determine the function and depth the scope statement hold.

The project life-cycle starts in the initiation phase where the scope is determined and sets the project on its progression towards completion. During the initiation phase the project stakeholders establish how the project will be measured and what success looks like (Project Management Institute 2008). The scope being defined helps provide a baseline of how the project manager will execute the project and provide guidance throughout the project lifecycle. The potential for failure is ever present in any project but when the scope is poorly defined the exponential growth for the potential for failure increases. The largest potential for failure for the ERP project is not involving the right people at the right time and not including key business partners into the decision process.

The scope of this project starts out at a high level as the implementation of a set of tools to replace the procure to payment systems in a single finished good manufacturing facility in a solidified wing-to-wing system and process model. For those areas that are going to experience high rates of change they must be brought in through the project’s lifecycle to build and maintain interest and buy-in. The implementation of this project at first seems to only define the needs of one section of the business. The rest of the business is still producing finished goods and relies upon the same legacy systems as the facility which is moving on to the new and improved ERP system. The first iteration also owns the responsibilty for building the figurative foundation to the house. The foundation will be the basis for future iterative roll-outs eventually involving every finished goods manufacturing facility in the business.

There are four areas that are going to be initially implicated by the implementation of the ERP project. This include sourcing, materials, finance and the suppliers. This includes all of the processes that are required to procure parts and material from a supplier to paying and building a product for the consumer. The scope of this project does not include the actions taken in some other parts of the business such as sourcing and branding finished goods, sales, legal or human resource functions. The scope of the project is the implementation of the procurement to payment process for the manufacturing company based on the finished good model.

The scope of the project is clearly defined and the finished good manufacturing facility is chosen so the next step in the process is to establish a baseline cost for the project and present that out to the key leadership named in the project charter. These key business leaders will need to understand what results and deliverables they will receive at the end of their project as well as the associated costs. The project’s charter precedes the project plan and outlines the scope, business case, identifies stakeholders and provides the project manager the authorization to start working on the project. By gaining this authorization the project manager could go out and build an estimate on the project.

Pricing and Estimation Techniques

We understand that this project which is a temporary endeavor to provide a unique deliverable at the summation of its lifecycle and with a project there is an associated cost to that project to complete it. The implementation of the ERP project will be done in iterative releases by implementing the ERP solution to each manufacturing plant in a series. With the risk and capital necessary to establish and maintain multiple teams the implementation of the entire program was defined to be in a series of plant by plant as opposed to each plant triggering to start and ending at the same time in parallel. This also provided the basis for the same implementation team to be utilized through the entire project if possible and a keen focus on knowledge transfer.

Understanding only one plant is rolling out with the changes is vital for providing an estimate on cost due to multiple factors. The first is the gaining of the understanding regarding the gravity of the changes for the plant and how much actual change will occur in the plant. There are multiple factories with varying degrees of production and complexity. The manufacturing facility that was chosen has recently introduced a new finished good and was built around lean management theory as to build a foundation for future improvement projects. While lean management does not play a role in the implementation of ERP it does put the teams in that facility in the right frame of mind regarding change and accepting those changes.

Throughout this entire project cost management will need to be taken into consideration. Management of cost and project management knowledge of how to manage those costs will come into play throughout the project lifecycle. The cost control methods used in this project include Earned Value Management and the establishment of an operating budget for the entire project. The Earned Value Management will be discussed shortly but first the operating budget will act as a reference tool as well as a deviation tracker throughout the project. The allotted budget (see below) will have specific sub-budget line items and the tracking of spend and deviation can be managed according.

The Earned Value Management (EVM) is more of a management tool than the operating budget as it takes it a few strategic steps further. The EVM tool will establish a base-line cost and measure the spend according to the value of the work that is being performed. EVM will be used to compare work performed with expected work perform and the associated costs with each deliverable area. The reason EVM will be used is for the simple fact that it has the ability to combine the areas of scope, schedule and cost, all of which the project manager is ultimately responsible. The earned value of the project is a calculation of the planned value versus the earned value and that is well suited for the type of project implementation the project team is looking to utilize.

The cost controls utilized for this project are based on sound financial and budgetary management practices as well as use of the EVM tool. Another way the project team will ensure strict adherence to project costs and allocation is by providing stakeholder reviews with the results of their EVM and budget. Through the use of project cost management and the tools of monitoring and controlling the project by documenting and utilizing EVM, the stakeholders will have a fair and accurate depiction of the project’s scope, schedule and cost as well as areas that have meet, exceeded or missed meeting their intended objectives.

These reviews by leadership will also act as a forcing function to the project manager to manage the project costs. When implementation is coming about there will be track leads assigned to each project area such as finance, sourcing, manufacturing and supplier. These track leads will inherently incur costs with their sub-projects that will need to also be monitored and controlled. Cost incurred at the work package level will ultimately impact the overall utilization of resources to achieve the cost, schedule and quality requirements. Cost management of these tasks also includes more than reporting spend to specific tasks. It also provides the project manager with the ability to take the appropriate actions to successfully meet the requirements. If there are projects that are finishing early and on budget or on schedule and under budget, the project manager could review the cost management tools and re-assign project resources appropriately. This allows further cost control on the project to ensure the entire project is within the scope, cost and quality parameters.

The costs of the project are controlled by the project manager’s actions to manage the budget. This is accomplished by utilizing the EVM tool, reporting to leadership, controlling track lead costs and allocating resources to where they are needed to meet the overall objectives and not just micro-project tasks. The cost controls in place provide the necessary structure and purpose to enable the completion of a successful project while controlling cost.

Trade-off Analysis

Managing a project requires a mixture of scientific and fact driven decisions but also a mix of artistic and instincful finesse to cross the finish line. There are times in a project’s lifecycle when key decisions need to be made in which could potentially change the entire make-up of the project. Some issues and problems that a project team faces have solutions that the key stakeholders were not expecting and are outside of the intened results of the project (Cooper, Grey, Raymond and Walker 2005). Changes in the project can be large or small and each require a different level of thinking and understanding to fully gather the impact of those changes. For areas that involve changes on a large scale or a large impact there needs to be an analysis completed. This analysis is a comparison between the benefits and risks of each decision based on a trade-off analysis view.

There are areas in the project’s implementation that stand out as key areas that need a trade-off analysis executed. These areas include training, support and module implementation. Each area has specific critical functions but can be accomplished in multitude of ways each having differing benefits. As the project team gather information on each of the areas they would be presented to leadership and each decision would be documented and executed as part of the project plan. This project plan would then be rebaselined and the appropriate cost, schedule and quality controls would still be utilized to manage the project.

When implementing a new system, especially when there is more than just a system change, the people that are using or supporting the system must be trained. The first area of trade-off is regard to training and how it is to be utilized to facilitate the transition of the newly implemented information systems and business process throughout the organziation as well as the outside entities, such as supplier, that have an impact on the manufacturing facility. Training provides mulitiple purposes, the first of which is training the user so they can fully utilize the system. The next are facilitates the buy-in of the key users and promotes an environment for acceptance regading the change. With supported training events that brings in trainees to interact in a real-life training exercise, the level of commitment is scaled up on both sides of the equation. On the other hand, training documentation denoting key changes and walkthroughs could also be sent to the end users with the guidance that these are the training tools they are afforded. This decreases the actual and perceived level of effort experienced by the end user and could impact the success of the program.

The level of training that was decided upon comes through a tier release process. This is a hybrid approach to the full in-person training and the system manual for completing tasks. Based upon the amount of end users impacted by the changes, the internal users would be afforded two options. Each track leader would conduct or facilitate limited in person trainings with follow-up webinar sessions. These sessions would occur at a designated point after the User Acceptance Testing but before the production launch. Other members that could or would not attend the training would receive the manual with instructions on how to conduct transactions. For external users such as suppliers, it was based solely on the amount of product the company purchased from them. The reasoning behind that is that high volume suppliers need to make many more transactions in the system as opposed to the low volume suppliers that would potentially have to review the training documentation for ever transaction. The high volume suppliers would receive in-person and webinar training and low volume suppliers would receive the training manuals.

Support of the system after implementation will be handled with a call center and the development and distribution of interactive training material. Initially it was thought that an increase in the support center was necessary to triage and fix user issues but with the implementation of the interactive user training the increase was not necessary. Only after the analysis was performed was it understood that to become effective with the system an increase in personnel was not necessary. The support team would still need to be knowledgeable in the functionality of the new system and that leads to the next area.

A critical and highly visible area of trade-off is the modules which are implemented. This means which areas the business is going live with and when they are going live with them. The trade-off analysis was conducted and to achieve the success warranted by leadership there were individual baselines set for each track within the project. Each section has three areas of high, medium and a low priority to ensure is functioning when the production go-live date is crossed. The results of the trade-off was based on the fact that while individual modules such as accounts payable could be maintained in a legacy platform it did not meet the intention of the overall project to secure a wing-to-wing solution. There was then a refocus on what was necessary and critical to ensure the system could produce the needed results.

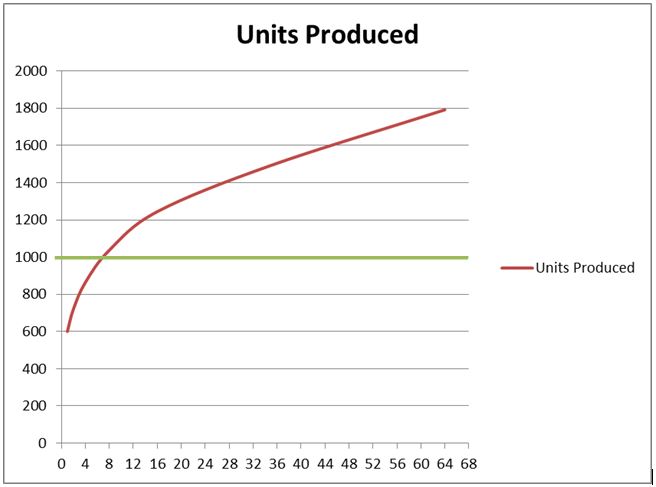

Learning Curve

The learning curve analysis showed that there are varying degrees of the learning curve dependent on what transactions are occurring with the new business processes and system. Overall this is not just a system change but a full ERP implementation into the manufacturing plant for a finished good product. While the system itself is new and will require adjustment to learn so will the new business processes that have been developed to support the new system.

The main objective of the learning curve analysis was how long it would be until the production rates could be meet. The current production rate is 1000 and through research and market studies a new implementation could decrease between 20-25%. Since this was a change of more than a new production line we added an additional buffer stating the business would hit a target of 600 units per week. In order to derive our numbers we had to utilize a learning curve percentage. According to Stewarts’s manual “Cost Estimator’s Reference Manual 2nd Edition”, the learning curve is between 75% and 85% for complex manufacturing and systems processes.

These results show that after eight weeks of production we can expect to meet our current production rates and will exceed those rates according to business need if necessary the following weeks.

Quality Management

Quality and continual process improvement go hand in hand with this project. The project plan includes implementation of a wing-to-wing ERP system. The requirements, based on a trade-off analysis and scope, are providing the functionality needed to become effective. The efficiency of the system will come during following process improvement initiatives but at first the goal is to be effective. The baseline for quality initiatives will need to be established with the project as well. The site selection is crucial for these future quality improvement projects because the first implementation is the foundation for all future upgrades and improvement projects.

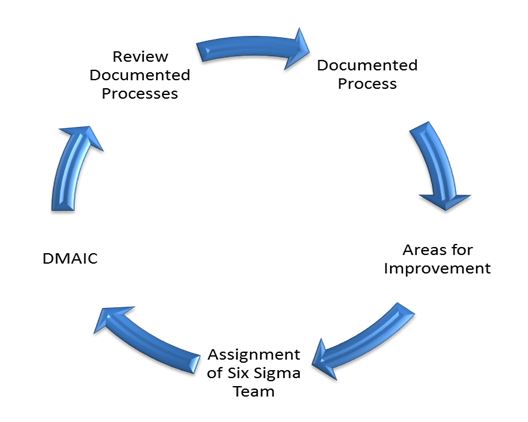

With manufacturing and the quality of manufacturing there is an establishment in the new rollouts of culture of lean. This includes combining efforts of lean managaement to reduce and eliminate waste in the process as well as implementation of six-sigma projects and methodology to reduce issues and create value. The project plan for this system takes into account many business process changes that will be felt throughout the lifecycle of the product. When opportunities arise and issues noted they are stored in a central location in a book of knowledge that will help changes in the future and to help prevent making the same mistakes over again.

The recommendation is to start with a culture of quality including lean management and six-sigma methodology. The time to fully embrace the six-sigma strategy is now when the business processes are documented and changes are occuring. The goal of six-sigma is to improve the quality of a product by analyzing the process and removing the causes of the problems. The processes for each area will be documented and become the potential area for the next improvement. This becomes a cyclical implementation of quality through six-sigma projects.

Quality is a central focus for improving the process once implementation has occurred. To maintain quality before and after there will need to be a push and support from leadership. The quality initiative process is documented above and denotes the cyclical nature of continual process improvement utilizing six-sigma as a basis for driving quality. The quality management will be based on thorough documentation of the implementation and support of leadership to go out and find the opportunities for improvement and take action.

References

Badiru, A., (2012). Half-life learning curves in the defense acquisitions of life cycle. Defense ARJ. 19. 3. Retriever from: http://www.dau.mil/pubscats/PubsCats/AR%20Journal/arj64/Badiru_ARJ63.pdf

Cooper, D. F., Grey, S., Raymond, G., & Walker, P. (2005). Project risk management guidelines, managing risk in large projects and complex procurements. John Wiley & Sons

Magal, S. R., & Word, J. (2011). Integrated business processes with erp systems. RRD/Jefferson City: Wiley.

Monk, E., & Wagner, B. (2009). Concepts in enterprise resource planning. (3 ed.). Boston, MA: Course Technology Cengage Learning.

Prencipe, A., Davies, A., & Hobday, M. (2007). The business of systems integration. Oxford University Press, USA.

Project Management Institute, P. M. (2008). A guide to the project management body of knowledge. (4th ed.). Newtown Square: Project Management Inst.

Stewart, R. (1995). Cost estimator\’s reference manual. (2nd ed.). Wiley.

Time is precious

don’t waste it!

Plagiarism-free

guarantee

Privacy

guarantee

Secure

checkout

Money back

guarantee