Thomas Built Buses, Research Paper Example

Executive Summary

Intermittent changes in the supply chain system of every company be it in the manufacturing or the service sector, especially given the fact that the unbridled economic foxes of competition are poised to eat up the lame ducks of inefficiency in our ever increasingly sophisticated global economy. These notwithstanding, just a handful of companies are able to commit to a regular policy of comprehensively assessing the integral supply chain that keeps them and their customers connected.

Incidentally, this report is primarily centered on making a strategically leaning sourcing policy model that specifically looks at the diverse facets of the supply chain management structure of the Thomas Built Buses company. It is fundamentally aimed at critically examining the numerous manufacturing processes in the Thomas Built Buses company spanning all aspects of the conventional metal casting activities to the adoption and implementation of software driven technologies to the entire management process.

The report also looks within the supply chain routes to establish a basis upon which to gauge the working relationships with main supply chain partners on the one hand and mainstream competitors on the other hand. Particularly, it is acknowledged that thanks to software technology a significant chunk of the labor intensive inputs stemming from the main supply chain routes down to the manufacturing process have been profoundly enhanced. It therefore provides a credible analysis basis for this report to look into the deeper dimensions of the decision making model and how that has ultimately contributed in a surge in efficiency in the supply chain process.

Closely integrated into this report is the value analysis that will provide the framework upon which to asses quantitative financial factors against other subtle non-quantifiable strategic policies that are within the overall supply chain system in place at Thomas Built Buses. For good reasons, the choice of this posture comes with the advantage of leveraging critical policy making latitude required to augment the value chain indicator in addition to the provision of a rapid response mechanism to respond to unforeseen forces in the supply chain line.

Finally, this report will be presented in the following pattern. It begins with an introduction that will succinctly usher in the background environment that basically highlights the current state of the Thomas Built Buses company and its constituent elements. Next is a presentation of the central structure of the theoretical and applied analysis of the diverse facets of the supply chain system in use at the company under discussion. It closes with a recap of the salient elements contained in the report and the last word.

Introduction

Integral to the success of any commercial venture depends on the efficiency of the supply chain management system in use. It is against this background that this report will fundamentally conduct an exhaustive look into the supply management chain model adopted and used by the Thomas Built Buses company based in North Carolina, a leading manufacturer of commercial school buses for the American and Canadian markets. The essay will particularly be limited to the operations of Thomas Built Buses over the last fiver years alongside how the company has used its current supply management system to make significant gains in significant markets in the United States which was hitherto considered inconceivable.

Critical to the operations of Thomas Built Buses lies the fact that exactness, efficiency, continuity and punctuality are right in the height of all that the company is about—within the context of the supply chain management process in use. This has being translated into the timely delivery of the required raw materials and supplies that are used to produce its finished goods. But most importantly, the scale of doing so is in many ways making the cost of production fall whilst facilitating the maximization of profits not to even mention the overall contribution this has on the brand name of Thomas Built Buses.

Typically, it is not farfetched to look at supply chain management case study from the perspective of the significant successes chucked by some of the pioneering rapid response corporations within specific segments on the market. Indeed, the process of growth achieved by most of these model corporations such as some of the electronic and hi tech giants in Silicon Valley can best be gauged by understanding the transition phases that characterized their historical existence. It becomes evident from their growth trend that much of what has been achieved came on the heels of viably active supply chain management policies. Put together, the fundamental lesson that can be obtained here is that the sweeping dynamism in supply chain management augmented by hi tech innovations provides answers to deep seated questions regarding how to achieve strategic potency in the overall quest to remain competitive. Consequently, replicating some of the best practices in industry is certainly the best way to go even when it comes to questions of supply chain management.

Environmental Background

Spanning a period of over seven decades, Thomas Built Buses has gained the reputation for the efficient manufacture of large public buses of every diverse types and uses for its clients. As of 2010 the five hundred million dollars worth company, located in North Carolina has provided buses on a regular basis to its customers with adequate precision, with this success has come an increasing level of sophistication in the process of its supply chain. Among other things, the company has to make ready to access responses to a host of vendors across several locations thus making it imperative for the company to be able to be at par with the demands of the timely delivery of its products at every given stage of its production process.

Fig. 1

It is with this in mind that this report will fundamentally, seek to conduct an exhaustive analysis into the contending internal dynamics of both the micro and macro factors that work together to ensure the efficient production of its goods and services within the milieu of contemporary dictates. Critical to the process in use at Thomas Built Buses is a planning procedure that is electronically coordinated to ensure that its operations are sensitively integrated within a comprehensive supply chain planning, manufacturing insights, visibility solutions among other things to ensure that the bulk of the sophistication that comes with the production process whilst within the same breadth increasing the individual parts of the operational processes.

The electronically managed planning system used to coordinate the supply chain management process has the advantage of making the management of multiple source inventory demands very easy and efficient. What the electronic system does is that the system wide coordination makes it easy to replicate deliveries as and when they come in without necessarily going over the entire MRP across board. Essentially, the customer and the supplier are both better off at the end of the day because both parties across the opposite ends of the stick can benefit from customized demand information which is crucial for the customer and the supplier to be able to make intermittent adjustments at the different production levels, thus resulting in a significant elimination of the tedious and laborious process of manually collecting information. Therefore time becomes efficiently used and cost is also considerably sliced in favor of maximizing profits.

Gauged from the manufacturing insight platform, the Thomas Built Buses company is able to ensure that data is collated very rapidly from more than one source like the ERP systems to be integrated into a the general data pool of the company so that they can effectively carve out the final picture of the supply and demand sides of their production with tact precision. Indeed, as stated earlier the rapid response coupled with the intermittent adjustments put together with the manufacturing insight aspect makes it easy for the company to make sudden detours in response to an unexpected change in the supply chain process to augment demand pool.

In order words the Thomas Built Buses company is defined within the paradigms of engaging a supply chain process that is essentially very proactive vis-à-vis planning and product delivery to its host of customers with time and speed serving as an integral component of the entire manufacturing process. It also makes forecasting into the future and how that can play into the operations of the company. With this policy in place to guide its entire supply chain management process, the company effectively revolves around deeper planning, rapid responsiveness, and elimination of outmoded inventory procedures.

Thus far, with all the positives associated with the company as stated above, this report will critically evaluate all the internal dynamics of the supply chain system exclusively used in the Thomas Built Buses company with the aim of identifying the rough edges that can be smoothened to enable the company consolidate if not improve its domestic and international gains.

Organizational Analysis

Developments in recent times in the auto industry has not been very pleasant partly because of the decline in growth of the global economy and most importantly the growth figures as forecasted for the United States, the single largest auto market in the world has been very distressing (Reference). The indication is that Thomas Built Buses being a major player in the industry has to brace up for the challenges posed by the happenings on the market. For this reason it is very imperative to ensure that the strategic policies resonate a sound sense of internally driven viability to address the market challenges both within the medium to long term framework.

Taking cognizance of the fact that general demand for auto products has become very volatile, manufactures including Thomas Built Buses have to come out with ways to significantly cut down on costs as well as ensure timely delivery of products to customers (Davis, 2001). Consequently, producers should leave no stone unturned within their supply chain system to ensure that these basic requirements are tentatively met.

Having said so, suffice to take a brief look at some of the contending issues that constitute the theoretical dimensions of a typical supply chain system. Doing so will serve as an orienting platform to usher in the deeper discussion of the issues at stake in this report. Akkermans et al (2003) describe the supply chain management system as all aspects of the coordination processes that take place between suppliers, manufacturers, distributors, retailers and customers of goods and services. At the heart of all the processes involved in the supply chain management process is the accessibility to information by all the various entities involved in the decision making processes that ultimately churns out the good or service in question to the ultimate customer (Davenport & Brooks, 2004). In a monumental study conducted by Hendricks et al (2007), it is proven that the bulk of the cost cutting process depends on the extent to which efficiency can be achieved in the supply chain system.

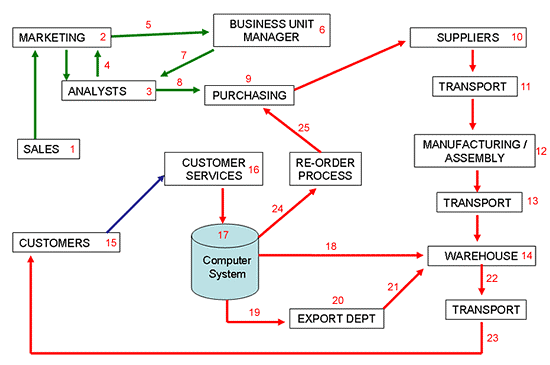

Figure 2. Below presents a diagrammatic illustration of the processes that go into the supply chain process in a typical system.

As stated earlier in this report, the most salient operational activities of the Thomas Built Buses Company are fundamentally technology enhanced. For instance, the incorporated hi tech devices within the company enables a system of effective manufacturing insight. This function fundamentally enables the collection of important input data from multiple sources within the supply chain to the centralized pool to ensure that relevant information is readily accessible at any given time along the production process. The information gathered is also critically studied by all parties involved in the manufacturing process. In studying the information, manufacturing parties are able to make queries, suggestions and improvements along the manufacturing process before eventually turning the final product out.

Using this method of manufacturing insight enables the Thomas Built Buses company to keep a watchful tab on the manufacturing process with the primary goal of keeping and responding to the expected and unexpected components that feeds into the overall planning process. It goes without saying that effective planning is a policy that is very synonymous with the practices of Thomas Built Buses. Being the case, the company is strategically able to respond in a very timely manner to all developments within the loop; it also becomes capable of scaling down the use of outmoded inventory alongside enhancing the longer term visibility of inventory.

It also uses similar technologies to support its process of choosing a suitable vendor to provide quick and adequate supplies thereby technically cutting down the risks that comes with investments.

Problem Identification and Resolution

The advent of globalization and its attendant wave of unprecedented competition has made the need for an efficient supply chain policy inevitable. The existing trends in the entire industry further provides ample justification of the need to make supply chain systems an integral leverage that will drive success. It is against this background that this section of the essay will be dedicated to taking a painstaking evaluation of the internal dynamics of the supply chain process in use at Thomas Built Buses. The idea is motivated by the need to highlight some of the rough edges in the system so as to come out with a comprehensive way of leveling the rough edges whilst consolidating the gains derived from the existing best practices.

For all intends and purposes, the current supply chain policy being used at Thomas Built Buses conspicuously fails to acknowledge a painful reality of the current auto industry. The truth is that there is an unprecedented level of customer volatility on the market due to the availability of a luxury of alternatives across the market. It is this truth that has played into shaping the poor state of customer loyalty to specific brand names which was hitherto not the case. As a response to this development it is highly recommended that management of Thomas Built Buses come to terms with this truth which will subsequently give them the leverage to churn out appropriate policy responses to address this anomaly. This can be done in many ways, but primarily the supply chain system should respond to this volatility with a complementary policy of increased flexibility, innovation and tact response to both current and emerging realities. It calls for a break in conventions for the more potent approach to shifting gears.

As of today, the bulk of the all the sourcing processes of Thomas Built Buses are from the United States. It is no secret the kind of implications this policy practice has on the cost accumulation process and how that also poorly impacts on inventory. The time has therefore come for management to re-consider this facet of their sourcing policies. In the most practical terms this means radically considering sourcing from countries or locations outside the United States that are considered low-cost. In doing so, it will serve as a genuine boost to the manufacturing processes in Thomas Built Buses. This should however be treated with caution bearing in mind that low prices do not necessarily represent all there is to the industry.

Management must adopt a holistic approach to addressing the overall question of sourcing as part of the process of choosing the most ideal destination that best serves the cost cutting goals. It involves a complete look at indicators such as the total costs involved in choosing a specific sourcing location, the logistical framework among other things. It simply forms part of the collective so-called best-cost-country sourcing policy. Management will be better placed to place a monitoring tub on the dynamism that will eventually feed into viable supply chain policies.

Another important area that the current supply chain management system in use at Thomas Built Buses is found wanting is in risk management; that even includes both real and perceived risks along the chain system. We live in a day and age that risks have become more threatening than they have ever been at any point in human history. It therefore becomes imperative to make it a corner stone of policy formulation and implementation. A very wise to do in the case of Thomas Built Buses is to come out with a policy of diversification that will facilitate the creation of a broad array of alternatives to sustain the supply chain management practices. This should be backed by tentative time-bound information relay to complement the act of spotting risks within the system and thus coming out with the right pro-active responses to them. Overall, Thomas Built Buses will have the advantage of placing value on their services as part of the main goal of enhancing efficiency in supply chain practices.

It is worth acknowledging that thus far the level of transparency and accountability within the supply chain structure of Thomas Built Buses is pretty much up to contemporary standards. Nevertheless, a considerable degree of room remains for consolidating the gains chucked in this regard for a number of reasons. For instance, taking cognizance of the scale of internationalization that comes with the operations of Thomas Built Buses it is imperative that transparency and accountability feature prominently as part of the process of reflecting high corporate governance regimes. It is all the more true bearing in mind that with internationalization comes with increasing responsibility to meet legal obligations. Information flow is integral to the process of transparency as stated in the preceding paragraph. What is also important is that the information flow should be bilateral with all sides held to the same level of accountability and transparency.

Environmentally Sustainable Supply Chain Management

Experts have predicted that the steady recovery of the United States economy signals a new aura of increasing demand for auto products bearing in mind that the United States domestic market serves as the industry’s most vibrant base. This projected growth in demand and corresponding production comes with its own baggage of responsibilities chiefly among them is the capacity to respond and address the environmental rhetoric that has permeated the industry over the last several years. To this end, it has become imperative for Thomas Built Buses to augment its ability to enter this new dispensation by structuring its supply chain system to reflect a more responsible environmental consciousness.

The biggest policy concerns have been centered on massive public outcry over emissions, natural resource usage, waste disposal and a host of others. The drive towards environmental consciousness should therefore gyrate from this hinge. Clearly, the United States depends on massive exports from resource endowed countries to sustain its domestic auto industry, given the international pressure been brought to bare on the United States government from global public opinion, indicators are clearly pointing to a future defining moment that the United States government would come out with stringent regulations and legislations to address these environmental concerns. Taking cognizance of this, the most prudent approach to fitting into the emerging environmentally charged dispensation is to act internally through policy implementations especially at the supply chain level to reflect this inevitable drive.

Failure to respond proactively makes the Thomas Built Buses vulnerable to the aggression of the current state of economic globalization that is sweeping the world at an alarming pace. It should be noted that globalization is certainly shifting the corridors of conventional market safe havens and the consciousness that comes with this especially from customers will soon crystallize into a consented force capable of crumbling the status quo.

It is also common knowledge that every product’s life cycle is intertwined to the supply chain system put in place to facilitate the production of the product in question; the same can be said about environmental implications on the supply chain management process. Specific emphasis is placed on the resource factor mentioned in preceding paragraphs. The supply chain system is supported by everything that has got to do with the extraction process of raw materials, converting these raw materials into useful input factors, the final product, recycling or destroying the product at the end of its life cycle. Thomas Built Buses therefore has the onus of coming out with measures that will ensure that it clearly remains within the safeguard limits of environmental sustainability in its quest to enhance competitiveness beyond its core domestic market area.

Summary

With the events of our day and age as a reference point, the corporate world has become synonymous with competition along every front; with this trend comes the question of achieving and maintaining efficiency most especially along the production lines. With this in mind there is no doubt that supply chain management policies serve as the pinnacle of events that can shape the direction to be towed. For this reason, this essay was dedicated to looking at the supply chain mechanism that supports the manufacturing process of Thomas Built Buses, a leading manufacturer of standard school buses for consumers within the United States and Canadian markets.

A key motivation for giving premium to supply chain management in this essay is underscored by the realization that an effective supply chain management system will enable the company to be better placed to initiate definite customer satisfaction that will eventually boost profits. The essay was guided by the definition offered by Henk et al (2003) that: “an organization is better placed through supply chain management processes if the organization in question is able to marshal the right input goods and services to the locations that they are needed at the right time, the exact quantity and at an optimal cost.”

With this as the background, the essay basically reflected the extensive study carried out about the Thomas Built Buses company. The essay essentially is divided into constituent parts to address all the diverse parts that are of interest to this author and most importantly have a significant bearing on the study as a whole.

In analyzing the supply chain processes in this study, a major issue highlighted had to do with the role of information communication technology in the supply chain management processes at Thomas Built Buses. Thanks to information technology delays associated with manual and laborious activities had been significantly cut down. This means that speedy delivery, a major indicator of efficiency in supply chain management has been optimally addressed. As a company Thomas Built Buses has every reason to take the operational dynamics of its activities very seriously, for this reason the study looked at the operational environment of the company through the lens of the micro and macro environmental factors. The goal is to see how this plays into affecting the success level or otherwise of the company from a strategic point of view.

Notwithstanding the profound level of efficiency displayed in the operational system upon which the supply chain practices hinges on, the study did identify a number of grey spots within the supply chain system that deserves to be given immediate attention granted the company is determined to remain competitive on the market. Among other things, customer volatility, transparency and accountability, and sourcing choices as the major constraints to the effectiveness of the supply chain system being used in the company. Naturally, the essay provides credible suggestions as to how to address these concerns in a favorable manner.

References

Davis, J., Some Assembly Required, zugegriffen am, Accessed on February 12, 2010 from. http://www.business2.com. Business 2.0: 2001.

Henk A. Akkermans, et al. “The impact of ERP on supply chain management: Exploratory findings from a European Delphi study.” European Journal of Operational Research 146 (2003): 284-301, 286

Karl Ulrich, “The Role of Product Architecture in the Manufacturing Firm,” Research Policy 24 (1995): 419-40.

Kevin B. Hendricks, Vinod R. Singhal, and Jeff K. Stratman. “The impact of enterprise systems on corporate performance:A study of ERP, SCM, and CRM system implementations.” Journal of Operations Management 25, no. 1 (January 2007): 65-82.

Metcalf, Sara Susanne, A System Dynamics Exploration of Future Automotive Propulsion Regimes, MS Thesis, Sloan School of Management, MIT, 2001.

Thomas H. Davenport and Jeffrey D. Brooks, “Enterprise systems and the supply chain.” Journal of Enterprise Information Management 17, no. 1 (2004): 8-19, 9.

Time is precious

don’t waste it!

Plagiarism-free

guarantee

Privacy

guarantee

Secure

checkout

Money back

guarantee