Triborough Bridge, Research Paper Example

Abstract

Triborough Bridge was constructed between 1929 and 1936 by O.H. Ammann. The RFK, Robert F. Kennedy Bridge, which was formally called Triborough Bridge, is a complex bridge. It is 3 bridges, an overpass, as well as 14 miles of advance roads linking Manhattan, the Bronx, and Queens. Triborough Bridge falls in the category of suspension bridges. The main components of this bridge are cables, ground anchorage, and other stiff steel structures. If it was constructed today, this bridge would integrate the modern technology in the design and implementation phases.

Introduction

The RFK, Robert F. Kennedy Bridge, which was formally called Triborough Bridge, is a complex bridge. It comprises of three different bridges in the US city, New York. This bridge serves the regions of Queens, Manhattan, and the Bronx in the City. The bridge was renamed in 2008 after the late senator Robert F. Kennedy of New York. The opening of RFK Bridge was in 1936 although a bridge that connected Manhattan, the Bronx, and Queens had been in the development phases since 1916. Surprisingly, construction of the bridge started on October 25, 1929. This was the day that followed the stock market’s crisis. This contributed to the bridge’s miserable financial condition. Therefore, working on the bridge went to a standstill in the spiral of 1932 since the task lacked adequate funding. This did not recommence until November 1933. The New Deal funding supported the project for sustenance and the Triborough Bridge officially opened on July 11, 1936. Therefore, the New Deal contributed largely towards this project, which was an opening for US residents. The history of RFK Memorial Bridge is associated with Depression. It is evident that the very design of the bridge, as well as its spans had to be tailored out of the Depression. This would ensure it to be lighter than before and thus more aesthetically satisfying (Jackson 137).

The initial design of the bridge was supposed to comprise of two decks nevertheless, there was deduction to have it be one. This Memorial Bridge is in fact, three bridges that assemble at the ring plaza above Randall’s Island. They disconnect into twirls and cloverleaves that point into twelve directions. For instance, Randall’s Island got its title after Jonathan Randel, who acquired it in 1784. Similarly, his descendants vended the island in 1835 to New York City. Therefore, it forms a park with several outstanding recreational amenities. There is also a recreational area on the Astoria Queens waterfront of the delay bridge at the periphery of a vigorous working class environs. The overall outlay of this Memorial Bridge, RFK was $60,300,000. The New York City, the bonds selling and the Federal Public Works Management, paid this. In the end, the bridge ended up costing higher than the Magnificent Hoover Dam. At Hell Gate, the gorgeous, light blue gray extent of the bridge that traverses the East River is 2,780 feet through anchorage to anchorage. In addition, the anchorage-to-anchorage extent of the elevated bridge above the Harlem River in which it streams between Randall’s Island and Manhattan is 770 feet.

Further, the extent of the tether bridge above the Bronx Kill is approximately 1,600 feet. It is estimated that around 200,000 automobiles cross all three extents of the bridge each day. There is a charge of $6.50 in cash for drivers who cross this bridge one way. However, drivers who operate on E-Z pass just pay $4.80. There are also provision of walkways in all of the spans, which provide spectacular outlooks of the Hell Gate Railroad Bridge and Manhattan skyline. The sidewalks in each of the three sides have the obligations for the bicyclists to saunter their bicycles transversely because of the safety concerns. Nevertheless, bicyclists have overlooked the signs showing this obligation. Therefore, the Government of New York City has suggested that the TBTA ought to re-examine this bicycling ban. There is also obstruction of handicapped access by the stairs on the 2 km Queens leg. Similarly, the Queens stairway next to the southern face was destroyed at the start of 21st century. This led to isolation of the pathway, but the incline of the Wards Atoll at the edge of the walkway next to the northern face was advanced in 2007. The Bronx span’s two sidewalks are linked to only one slope at the Randalls Isle. In 1986, the Civil Engineers of USA chose the Triborough Bridge Scheme as a National Historic Engineering Landmark. It was on August, 1996 when motorists initially had the capacity of paying using the E-Z Pass. This was in a track for automatic invent apparatus at the Randall’s Islet toll on plazas.

Figure 1Triborough Bridge

Location of the building

The construction of the Robert F. Kennedy Bridge started on October 25, and was completed on July 11, 1936. It is indeed 3 bridges, an overpass, as well as 14 miles of advance roads linking Manhattan, the Bronx, and Queens. The Manhattan bough comprises of the Harlem River Bridge that connects the FDR Drive, Harlem River Drive, as well as 125th Street, Harlem’s cultural and commercial center. Similarly, the Bronx Crossing guides motorists to spots north via the Deegan and Bruckner expressways. It also shows the locality of the Port Morris and the South Bronx Industrial Area. Moses initially anticipated that the Manhattan limb of the Robert F. Kennedy Bridge has to be built at East 103rd lane. This was to evade the mental organizations on Randall’s Island.

There was a consideration that the East 103rd Street would offer a convenient substitute to the Queensboro Bridge. This is because the bridge was working at its intended capacity. Nevertheless, the East 125th Street position that was formerly acquired for the RFK Bridge was utilized instead. The tough problem outlined in this case is that of the 125th Street Manhattan limb of the crossing. For example, any kid could observe that it felt right much further at 103rd Street downtown, in a straight line with Queens. Therefore, it would have evaded interference of the Randall’s Island organizations. The single-deck elevated extent above the Harlem River linking Randall’s Island and Manhattan consisting of three autonomous truss spans. The major extent, a 310-foot-long mobile central truss extent, have a permanent 55 feet clearance. However, this can be elevated to a location 135 feet over the Harlem River. At the same time, the mobile deck droops from the dual 210-foot-high looms, whose blueprint is George Washington Bridge borrowing.

Culture and society

There are several cultural and social impacts associated with construction and utilization of Robert F. Kennedy Bridge in the New York society. For instance, the quantity of human force that anticipated for the construction this bridge provides some initiative of its immensity and impacts. It is approximated that over five thousand workers would be operating at the site. It also estimated the construction of the memorial bridge would generate over 31,000,000 man-hours in over 134 cities. Therefore, the Triborough is should not be taken merely as a crossing nor yet a bridge. It is an enormous artery, linking three municipalities of the city. It also connects borders of adjacent states and counties. It is not just a way for trucks and automobiles, but also a universal city development. The Bridge will also ensure reclamation of neglected areas. This will offers residence next to its borders with playing facilities, esplanades, landscaping, as well as access to the outstanding new parks (McCullough 34).

New York City is an old society. This can be confirmed through the study of the relics, as well as mementos of the early white occupants of the state. There are evidence of old coins, pipes, substructures of city development and change. It is evident, that in the initial year of function in 1937, about 30,000 vehicles daily crossed the Robert F. Kennedy Bridge. This subsequently improved the living standards of the residents. Therefore, the Robert F. Kennedy Bridge is a project to stimulate the imagination. This is in terms of its proportions, which is heroic. The construction approach inclines would be so enormous that accommodate sizable residence buildings. The houses would be bulldozed and hundreds displaced to pave the way for construction.

The concrete masses, in which its wires would be entrenched, would resemble Egyptian Pharaoh built pyramid. The roadways would also be broader than the broadest roadways built by the Romanian Caesars. Further, to build the anchorages as well as to pave the roadways would need sufficient concrete to cover a four-lane road connecting New York with Philadelphia. This should be adequate to reopen Depression-closed cement plants Mississippi from Maine. There this would also poses a greater cultural and social challenge to the society. Similarly, to generate the girders where the concrete has the foundation, Depression-banked heaters would be needed to be fired up at different Pennsylvania steel mills. All these and other cultural and social factors are contribution from the construction of the Robert F. Kennedy Bridge.

Design and Construction

A bridge is one of the most critical elements in civil engineering and road construction. This facility attracts the attention of people from diverse professional background because of its impact on the economy and safety of the road users. With regard to safety, the contractors and design engineers made various considerations constrained by the availability of materials, projected use, and the nature of landscape in which the bridge was to be constructed (Moses 3). This section discusses these considerations while seeking to ascertain the design and construction of Triborough Bridge.

Triborough Bridge falls in the category of suspension bridges. In such bridges, cables manufactured from high strength, and zinc coated steel wires are used because of their suitability in covering long spans. The choice of these materials is informed by the economical nature of such long bridges at the excess of 1000 ft. Although the use of such cables leaves the bridge with superb aesthetic value, its choice in the construction of Triborough Bridge is informed by high strength and resistance to corrosion (Haight 32).

The fundamental economic feature of this bridge, as occasioned by the utilization of high-strength materials while under tension load, is its lightness when compared to a considerably low dead load. However, this poses a threat of massive flexibility which may result in too much deflections under love loads and prone to vibrations. Although this class of bridges is not ideal for heavy loaded roads, the design for Triborough Bridges provides sufficient resistance to wind and seismic instigated oscillations.

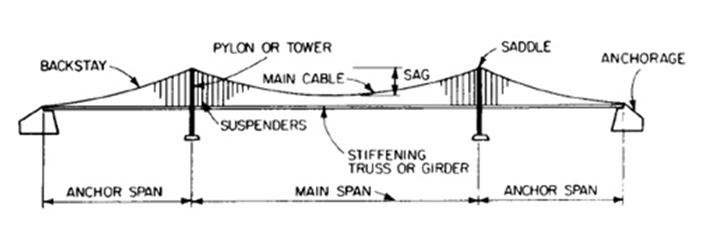

The main components of this bridge are cables, ground anchorage, and other stiff steel structures. Figure 1 below shows a typical suspension bridge which represents the general components of Triborough Bridge. For the sake of stability, the bridge has stiffening girders and trusses. The function of these components serves to equalize deflection brought about by concentrated live loads and spread these loads over other cables. The increased stiffness of these compared to those of cables makes this function efficient (Gandy 288). The shapes of cables are critical in determining the stiffness of the cable. Having round shaped cables as those used in this project enhances the stiffness of the cables. The anchorages are made from composite material comprising of steel structures as skeleton and concrete as the fillers and load absorbers (Stahl, 93).

Figure 2The main components of Triborough Bridge

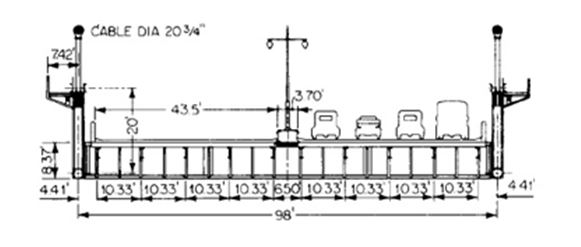

The Figure 3 shows a cross-section of reinforced concrete deck contained in the floor beams and supported on low ends by stiffening trusses.

Figure 3: The cross-section of Triborough Bridge

Triborough Design

For every design and construction of such a big project astute management team must be put in place to ensure smooth implement of preset design and material usage. This team is also charged with the responsibility of ensuring that necessary amendments are done during the execution of the project. During the construction of Triborough Bridge, Amman, who took over the design process after the works of Arthur Perry, kept the objective of construction but could not hesitate in making amendment whenever it was necessary. While Perry had come up with two steel towers and four cables for suspension, Ammann attempted to reduce cost construction by eliminating one deck, thus, leaving an eight-lane deck stiffened by trusses. The steel towers were further redesigned to allow further cost reduction. The process of redesigning saved an estimate of $10 million from the earlier budget estimates (Reier, 121).

In the new design by Ammann, two suspension cables of length 3104 feet were used between Ward’s Island and Astoria Queens Island. Each of these cables contained 248 cold processed, galvanised steel wires having a diameter of at least 0.2 inches. In his design, Amman deviated from the traditional methodologies of cable termination and used cable-bent post on anchorage ends.

The new design indicated in the new design reflected novel designs and construction with notable superiority over what Perry was proposing. Ammann’s new design entailed basic geometry and uncluttered lines. The horizontal struts hold these posts in place. In a bid to give the bridge an aesthetic touch, the tower tops were fitted with light posts. An outstanding and common method of construction of this bridge were manufactured off-site and ferried to the site via cranes.

The whole suspension structure was made up of stiffening truss of 20-foot deep, except for the floor beams that were made of a series of plate girders 90 feet long. The roadway lies in between the bottom and the top stiffening trusses chords that partially obscure the motorists view. The towers reflect new construction and design conventions. In between the tower legs are four vertical posts 93 feet deep that are purely ornamental.

By altering the design in this manner, the new designer spread a section of dead and live loads to the ground via cable bend’s strut post while the excess loads are expended through anchorages.

The single-deck lift span that is over the Harlem River between Randall’s Island and Manhattan consists of 3 independent truss spans. The main one is 310 feet long, movable and has a 55-feet fixed clearance but can be raised above the Harlem River to a 135-feet position. The movable deck is suspended from the two towers, with a height of 210 feet and borrows its design from George Washington Bridge’s design of winding 96 wire ropes around drums of 15-feet diameter. The movable deck is flanked by two fixed truss spans of 230 feet long. The Harlem River has two sidewalks and six traffic lanes and weighs 2,200 tons with a deck area of 20,000 feet-square deck area. This made it the largest bridge in the world during the time of its opening. Yet it was not the heaviest bridge due to Ammann’s efforts to minimize its weight.

Between the Bronx Kills, Ammann designed a steel truss bridge of three spans carrying eight traffic lanes over a single deck. The Bronx Kills truss span is in a permanent, fixed position and offers a vertical clearance of 55 feet. The design of the approaches and the toll plaza was a new engineering exploit. In the plaza proper, 1,700 concrete columns support a 390,000 square feet roadway area which is faced by a concrete wall of length 8,000 feet on all sides. The plaza consists 5,900 tons of reinforcing steel and 70,000 cubic yards of concrete. It is enclosed by two concentric circular ramps to get rid of left turns and grade crossings, as well as saving efficient movements within the toll plaza.

Labor Force

In 1933, Moses was appointed by Mayor Fiorello LaGuardia as the chairman of the Triborough Bridge Authority. Prior to the construction, Moses employed Othmar Ammann to as the bridge designer. The construction of the Triborough Bridge started in the mid 1930s, but it was at the time called “the Bridge to Nowhere”. The bridge was completed in 1936 when Moses was the chairman of the Tribobridge Committee. It took over 13 million working hours, within 134 cities and across 20 states for the engineers, ironworkers, surveyors, carpenters, draftsmen, sandhogs, electricians and labourers to finish the tunnel. The final rock that separates the tunnel between Manhattan and Brooklyn was holed through, in 1948. The majority of the laborers were local ironworkers union members some were from Brooklyn while others were from Manhattan Union and had previous experience in bridge building. The others were “boomers”, site supervisors and itinerant workers who often travelled from one construction site to another.

At a time, there were about 5,000 men working directly on the bridge. In fact, these were the only men who constructed the bridge together; other tens of thousands were involved in the preparation of the materials for making the bridge. The building project was so huge in the middle of depression to the extent of buoying the whole country’s economy on its own.

If It Were Built Today

The Triborough Bridge’s construction started in 1929 and completed in 1936. Although this is almost a century ago, the construction of this bridge is not very different from today’s bridge construction. The constructors most of the techniques that are still in use and will be used into the future. In the past few years, technological explosion has emerged and has led to the manufacture of advanced machinery and tools. Currently, there are construction cranes, which can help in lifting heavy objects in place of pulleys. This makes it easier and faster to lift heavy objects than was the case in 1929. The transportation equipment are now more advanced than they were in the 1920s. Instead of making several trips transporting wastes, debris and parts using smaller trailers and trucks, this could have been done using dump trucks and trailers if it were today.

Nowadays, parts of buildings or constructions are often prefabricated away offsite and transported for assembling at the site. If this technique were available during that time, the construction of the bridge would have been quicker, easier and more efficient. Furthermore, the superior shipping available today could have helped to move the offsite built parts the actual building site. The limited transportation available at that time demanded that they assemble most of the materials on site. Building materials could also be riveted, screwed and nailed together faster and more easily than the workers were able to when constructing the Triborough Bridge.

Most importantly, the increasing utilization of computers as well as other advanced technologies has facilitated construction processes. It is now possible to computer animate, computer simulate, draft and estimate diverse situations that had been done earlier using a paper and a pencil. Today’s greatest advantage is that there is the availability of ancestral knowledge regarding construction of such projects. The history mingled with the latest technologies can help in constructing bigger and more efficient projects faster than ever before.

Works Cited

Gandy, Matthew. Concrete and Clay: Reworking Nature in New York City. Cambridge: MIT Press, 2003.

Haight, Roger Q. “Cable Safety Factors for Four Suspension Bridge.” Journal of Bridge Engineering 4.2 (1997): n.p. Print.

Jackson, Donald C. Great American Bridges and Dams, John Wiley & Sons, New York 1984.; pp. 137-138.

McCullough, David G. The Great Bridge. New York: Simon and Schuster, 1972.

Moses, Robert. Public Works: A Dangerous Trade. New York: McGraw-Hill, 1970.

Reier, Sharon. The Bridges of New York. New York: Courier Dover Publications, 2000. Print.

Stahl, Frank L. Investigations of Fractures in the Anchorages of the Triborough Bridge,

Presented at 10th Annual International Bridge Conference, 1993, Paper IBC 93-39. Print

Zuss Noah C. “Triborough Bridge Renamed After RFK.” The Queens Tribune 05 Jun. 2008: Print.

Time is precious

don’t waste it!

Plagiarism-free

guarantee

Privacy

guarantee

Secure

checkout

Money back

guarantee