U.S. Army, Research Paper Example

Within businesses and organizations the importance of a management approach is essential in handling the daily operations and activities and putting the needs of the customer first in aligning with the expressed principles and goals of the organization. As organizations and business continue to grow they depend on a number of methodologies that are used in outlining their business objectives with their performance excellence. While also depending on management systems that aid them in managing their customers’ priorities and needs, and create a work culture that is centered on enhancing their work process, process improvement, and process controls. The management approach of Total Quality Management is one of the more popular philosophies used presently in organizations originating from the 1950’s and became popularized in the 80’s. Total Quality Management philosophy has been implemented in so many major corporations that it is the go-to approach for focusing on the performance excellence while focusing on the customers and the organization’s objectives. The U.S Army is one of the major organizations that has utilized the Total Quality Management Approach since the 80’s. They have dedicated much of their resources in trying to keep operations and activities in line. Total Quality Management provides a guideline and approach that regulates procedures, processes, policies, and manages the U.S Army organization.

Quality management, known also as quality control, is a system utilized by all types of businesses all around the world. This type of management system has the ability to assist any type of organization provide consumers with the best product and/or service possible by managing its activities, this points to an increase in its usefulness and productivity. Through the many types of systems used for quality management, a business can monitor and measure the quality of its products and/or services being offered to consumers. An effective quality management system helps a business to increase its competitive edge, increase its organizational development, highlight its customer satisfaction, and more.

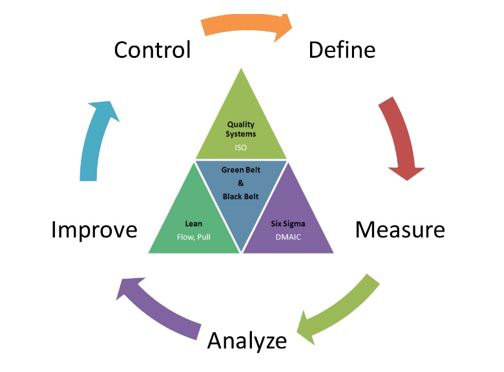

There are several methodologies and practices that are utilized in building performance excellence, those methodologies include, Continuous Quality Improvement (CQI) that is process used for ensuring the organization is improving their services to increase positive outcomes for their organization. It is known as cyclical, data-driven process that is a proactive approach in improving the organization while aligning the business objectives. Value Chain Analysis is another method that is used primarily in helping gain a competitive advantage over other organizations. “Value Chain Analysis describes the activities that take place in a business and relates them to an analysis of the competitive strength of the business. (Riley, 2012) According to Michael Porter the activities of an organization can be grouped into two categories, Primary Actives that focuses on creating and delivering a product or Support Activities that may increase the efficiency of human capital and effectiveness of the organization. Theory of Constraints is a practiced primarily used in project management that helps to specify constraints that might hinder the completion of the project. Just in Time is another practice that focuses on improving the return on investment for the organization is also improves efforts associated with carrying costs, and reducing the in-house process inventory. Six Sigma and Lean Thinking Method is a practiced that is used in many major corporations including the U.S Army.

Within the U.S Army, the type of quality methodologies and practices they utilize are plenty. Currently the U.S Army implements a practice known as Continual Improvement Process (CPI) that is known as an ongoing effort that systematically improves services, processes, and products within the organization. They decided to embark on this methodology when a major CEO told them that in order for them to do business together they must be more efficient. The General Benjamin S. Griffin and the army listened, he went out to tell the rest of the Department of Defense that this method was to improve the organization. “The DOD’s CPI program provides methods, tools, and philosophies that can be used to improve the way the Army works through training and certifying its workforce.”(Defense Talk, 2008) By implementing this methodology the Army has transition into a more efficiently run organizations. In order to do this they have systematically, use a joint-service sharing strategy and other models they have adopted from the Business world. The have seen improvements in quantity, quality, and safety. According to General Griffin, “If a Soldier shoots it, drives it, flies it, wears it, or eats it, Army Materiel Command probably has something to do with providing it,” (Defense Talk, 2008)

The Army is using the Continual Improvement Process with other techniques such as the Lean Theory in efforts to reduce waste and manage resources. After fighting in a major war recently that has come to an end, they must look for other avenues in helping to create a more efficient organization. The Continual Improvement Process is used alongside other quality practices that they used to strategize for the future. They developed an entire plan focused on preparing them for the future. As the future unfolds, they find their selves trying prioritize their time and resources in order to serve the purpose of the organization and the soldiers they have enlisted. By developing their Army Strategic Planning Guidance that outlines key steps for the next four fiscal years. The Army Plan (TAP) is aligned with the Department of Defense priorities to guide the Army. “The Army must transform itself from a force that focuses on counterinsurgency operation to an Army that is operationally adaptable, able to meet the range of Combatant Commander Requirements as part of the Joint Force, including counterterrorism and irregular warfare; deterring and defeating aggression; projecting power despite anti-access/are denial challenges…” (US Army, 2012) In realizing that not every soldier will be trained for war, the Army has adopted quality practices that “ensure both operating forces and generating forces are optimized and aligned to support Department of Defense and Department of the Army strategic priorities.” (US Army, 2012) The practices that are essential to their organization include developing leaders in order to meet future challenges. By doing so, they help to train, educate, and develop leaders to inculcate the priorities of the Army.

Another objective is to sustain the All-Volunteer Army that helps to improve the efficacy of the programs that continuously support families, soldiers, civilians, and wounded soldiers. “Develop, align, and integrate the Army Personnel Life-Cycle Model and processes to optimize soldier management and development.” (US Army, 2012) Not only does the army implement these practices but also chooses a Total Army Quality, “integrated strategic management approach for achieving performance excellence.” (APD, 2002) The formed the approach on the central factors of aligning performance excellence with the organizations strategic objectives, goals, and processes that are linked to optimize for quality in delivery, and services to the customers. This approach not only is beneficial to the organization and the customers, but is able to minimize the expenditure cost of the resources. At the core of the Total Army Quality approach are four principles that are the foundation for providing value to the improving the Army’s organization which include, leadership vision and commitment, mission and customer focus, employee empowerment, and continuous improvement. (APD, 2002) Under this approach the Army is allowed flexibility in the options available in providing process management to multiple fields throughout the organizations. The leadership is able to adapt to different philosophies, tools, and management that help to support the needs of the customer. In focusing on their principle to be Customer focus, the Army has named the mission of providing a national defense and security for the citizens (customers). “The sole reason for an organization to exist is to meet or exceed customer requirements.” (APD, 2002) The customer has the ability to decide the value of the organization based on the quality of the service, and the products provided. In achieving performance excellence all people and operations have to be focused on efficiently providing value for the customer. In alignment with their other practice of Continuous Improvement, within Total Army Quality, they have two levels, process and organizational. In both levels change is essential. In process level, managers are held responsible and accountable for process improvements and results achieved. Employees must remain focused on the customers’ needs, and strive to improve their processes. In organizational level, change management is pertinent providing a long range vision, setting long-term goals, and planning for the future in order to define areas for improvement.

Within Business, “A quality management system is a management technique used to communicate to employees what is required to produce the desired quality of products and services and to influence employee actions to complete tasks according to the quality specification.” (Abahe, n.d) Quality Management Systems are meant to line out a clear vision for the organization, uphold the standards of the organization, and helps to motivate, set goals, and direct the culture in which the organization operates. Quality management systems serves as a way for organizations to be able to produce higher quality in service, products compared to competitors, and to focus on supplying the needs of the customers. Dating back to the early 1950’s the interest of improving the quality within the organization was first invoke by Japanese companies that enlisted the aid U.S companies that have received help from the likes of W. Edwards Deming that invented his own system in quality management. Deming developed a 25 point system that communicated to managers on increasing quality within the organization. “According to Deming, there were two different concepts of process improvement that quality systems needed to address: (1) common (systematic) causes of error, and (2) special causes of errors.” (Abahe, n.d) Another prominent figure and pioneer of quality management systems was Joseph M. Juran who helped to define quality where the services should be reliable without any worry of errors. These qualities included, quality in design, conformance, availability, safety, and field use. As the Japanese companies flourished, Congress took interest and invited Deming, and others to provide a model system for U.S companies. ISO 9000 was invented that contained quality management systems that became the standards for the three major automotive companies, Ford, General Motors, and Daimler-Chrysler. However, the biggest approach came in the 80’s which covered the entire organization, Total Quality Management.

U.S Army has known the importance of quality management in their organization as they are faced with daily operations that pull management, staff, and soldiers in several directions. The Army has utilized quality management practices since the 1980’s when the Secretary of Defense in 1988, Frank Carlucci issued the move that was mandated for the entire infrastructure move to implement the Total Quality Management methodology. The purpose that the Secretary of Defense moved to this approach was to improve performance and efficiency. (Shinkseki, 2002) In particular at the time in the 80’s that government wanted to implement TQM, the Secretary of Defense wanted to the Department of Defense a much more competitive environment that required all the agencies within the department to practice business techniques that used the lowest cost per unit, and that budget was shrinking and needed to find ways to maximize their scarce resources.

Total Quality Management system focuses on the entire culture and attitude of the organization in helping to find ways in satisfying the needs of the customers and the business. Not only was the viewed shared by the Army, but “In 1993, the President of the United States initiated the National Performance Review (NPR) with the mission to make the entire federal government both less expensive and more efficient and to change the culture of the national bureaucracy way from complacency and entitlement toward initiative and empowerment. TQM is a method by which management and employees can become involved in the continuous improvement of the production of goods and services. It is a combination of quality and management tools aimed at increasing business and reducing losses due to wasteful practices. The culture requires quality in all aspects of the company’s operations, with processes being done right the first time and defects and waste eradicated from operations. The management approach of Total Quality Management is that is improving the performances of the organization on every operational level in finding efficient ways to use capital resources and human capital. Within TQM is the principle that is already utilized within the Army of continuous improvement as the organization strives to work together as a team flowing in the same direction towards the same goals. TQM focuses on encouraging the managers, leaders, and employees (soldiers) of the organization to be committed in improvement operations, management, and customers relations. In terms of the Army, encouragement is best served on the daily practices of trusting their subordinates.

The practices and systems within the Army are many, however, what the Army is focuses on is developing a Lean way of Thinking, by utilizing the Six Sigma Method. Six Sigma Method developed in the 1980’s from the Motorola company differs greatly from the Total Quality Management system that was implemented in the 1980’s for the Army. “Six Sigma differs appreciably from its predecessor – Total Quality Management (TQM). Six Sigma is highly focused and based on comprehensive performance and cost metrics. In many cases, TQM simply isn’t.” (Saxton, 2003) Six Sigma is a structure system that follows a statistical approach in process improvement using a variety of tools that include Total Quality Management (TQM), Just In Time, Statistical Process Control (SPC) and design of experiments (DOE). Within the Army the organization uses a fusion of Six Sigma and Lean Method. “The ultimate goal is to free human and financial resources for more compelling operational needs.” (Pyzdek, n.d) According the Army this fusion is necessary due to the fact that Six Sigma cannot improve the process speed or reduce invested capital at a dramatic rate, while Lean Method by itself cannot bring a process under statistical control. The Secretary of the Army, John McHugh stressed that the Lean Six Sigma system was essential in transforming the Army to build better for the future in supporting the forces presently. The organization must be flexible, innovative, and determined to provide the best products and services to the customers, while serving the needs of the organization and training up leaders. (Pyzdek, n.d) According to Griffen, “Applying continuous process improvement, Lean Six Sigma and other aspects of efficiency improves support to the service members in the field.” (Defense Talk, 2012) The Lean Six Sigma approach helps in providing more engagement, feedback, sharing of ideals, innovations, and cost benefits. That have spread throughout the organizations and closely related sectors in the field.

Although the Army is an organization unlike other traditional businesses, each organization must have a quality system in place that focuses on the needs of the customers, and performance excellence. Within the Army they rely on a number of quality practices including Continuous Improvement Process that is echoed in just about every system in practice that they utilized. Total Army Quality is manufactured specifically for the organization in driving home the central them of focusing on the needs of the customers while process improvement for achieving performance excellence. Their chose in quality systems are like most major corporations, relying on Total Quality Management in order to provide a more stable approach in process control, and improvement. However, unlike other organizations they have fused together to approaches in order to dynamically attack the capital returns, and resources within the organization. Lean Six Sigma has proven for the organization to be a new system in place that uses Statistical Process Control in order to systematically provide the tools for leaders in developing ways for change management and meeting customers’ requirements The techniques could use improvement, as they are not as easy to implement in such as complex and wide organization such as the Army. TQM systems within the Army must foster an environment or culture that breeds mutual respect between higher rank officials and their subordinates. .Input from lower rank soldiers is necessary in creating that workable environment where everyone adds value to the organization. Allowing soldiers to voice their feedback also helps with attitudes, production, and overall morale for the organization and how they treat the customers. When using the Six Sigma method it is important to remember to focus on the customer, while monitoring process improvement, and system interaction. Six Sigma was primarily developed as a way to control the waste, invention, and areas of management. In following the steps taken to monitor and improve the organization will be able to achieve performance excellence and the needs of the customers.

References

“Army Strategic Plan Guidance.” (2012). US Army. Retrieved from http://usarmy.vo.llnwd.net/e2/c/downloads/243816.pdf

“Army Taking Care of Business through Continuous Process Improvement.” (2012). Defense Talk. Retrieved from http://www.defencetalk.com/army-taking-care-of-business-through-continuous-process-improvement-15775/#ixzz2X5rY95wC

“Continuous Quality Improvement.” (n.d). CBCAP. Retrieved from http://friendsnrc.org/continuous-quality-improvement

Pzydek, Thomas. “U.S. Army Embarks on Improvement Using Lean Six Sigma.” Retrieved from. http://www.sixsigmatraining.org/leading-six-sigma/u-s-army-embarks-on-improvement-using-lean-six sigma.html#sthash.B81iWNnC.dpuf

“Quality Management Systems.” (n.d). Abahe. http://www.abahe.co.uk/business-administration/Quality-Management-Systems.pdf

Riely, Jim. “Value Chain Analysis.” (2012). Tutor2U. Retrieved from http://www.tutor2u.net/business/strategy/value_chain_analysis.htm

Sommerville, J. (1994). Multivariate barriers to total quality management within the construction industry, Total Quality Management. Vol.5.

“Total Army Quality Management.” (n.d). APD. Retrieved from http://www.apd.army.mil/pdffiles/r5_1.pdf

Wellman, Richard, Box, Thomas, Saxton, Susan. (2003). “Six Sigma and the U.S Army: A Potential for Excellence.” Allied Academics International Conference. Retrieved from http://www.sbaer.uca.edu/research/allied/2003/Management/new/04.pdf

Time is precious

don’t waste it!

Plagiarism-free

guarantee

Privacy

guarantee

Secure

checkout

Money back

guarantee